Pressure vessels, drums, funnels & special designs made of stainless steel for pharmaceuticals, cosmetics & fine chemicals that set new standards

Increase quality & safety by minimizing particle adhesion

- Contamination-free production: Stainless steel surfaces from BOLZ INTEC are optimized for industries with the highest demands on hygiene and cleanliness.

- Reproducible product quality: Stainless steel surfaces from BOLZ INTEC are flawless and reduce the risk of production downtime & product recalls.

- Compliance with the highest standards: Stainless steel surfaces from BOLZ INTEC guarantee compliance with GMP and EHEDG standards.

Over 2,000 customers in 48 countries place their trust in our stainless steel containers, drums & appliances

BOLZ INTEC stands for innovation, quality and precision in the manufacture of stainless steel drums, pressure vessels, apparatus and special constructions according to the requirements of our customers. As a long-standing partner to the pharmaceutical, specialty chemicals and cosmetics industries, we create solutions that set standards in quality and hygiene, bring our customers decisive economic advantages and increase product and production safety.

Our stainless steel containers and special designs are manufactured in accordance with GMP and EHEDG Hygienic Design guidelines. They are predestined for use in hygiene-sensitive environments. BOLZ INTEC's practical product development guarantees their uncompromising quality and safety.

15 of the 20 largest pharmaceutical companies worldwide are customers of BOLZ INTEC

15 of the 20 largest pharmaceutical companies worldwide are among BOLZ INTEC's customers

Market capitalization of the top 20 pharmaceutical companies in 2022, source: GlobalData

Customers from these industries increase their efficiency with stainless steel tanks, apparatus and structures from BOLZ INTEC

Product portfolio of BOLZ INTEC

Pressure vessel

Stainless steel drums

Funnels & special funnels

Special constructions

The Optimized Grind Finishing process (OGF)

In the pharmaceutical, chemical and food processing industries, minimizing build-up in containers is a critical factor for efficiency and quality. The build-up of substances on the inside walls of containers can lead to increased cleaning effort, product losses and contamination. This costs money and ties up resources. Especially in industries where EHEDG (European Hygienic Engineering & Design Group) certification and hygienic design are becoming increasingly important, minimizing adhesion has become a critical factor.

Research carried out by BOLZ INTEC in cooperation with the University of Constance has shown that the way in which stainless steel surfaces are removed plays a key role in minimizing adhesion. Different grinding methods result in different adhesion behavior, despite the same Ra values, and the OGF process from BOLZ INTEC leads to a lower adhesion of particles.

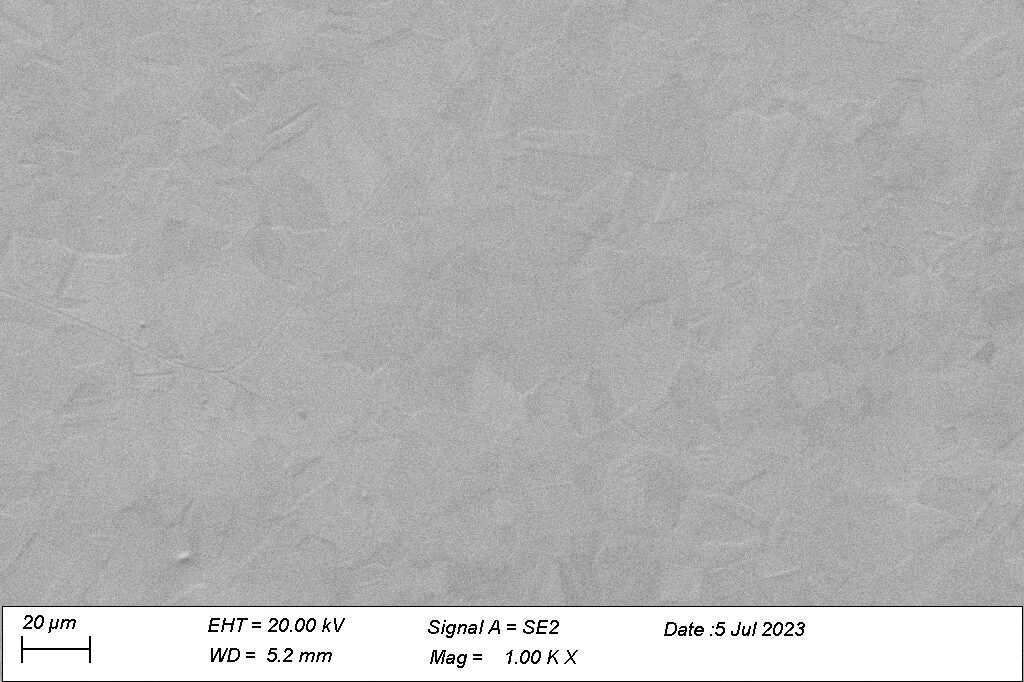

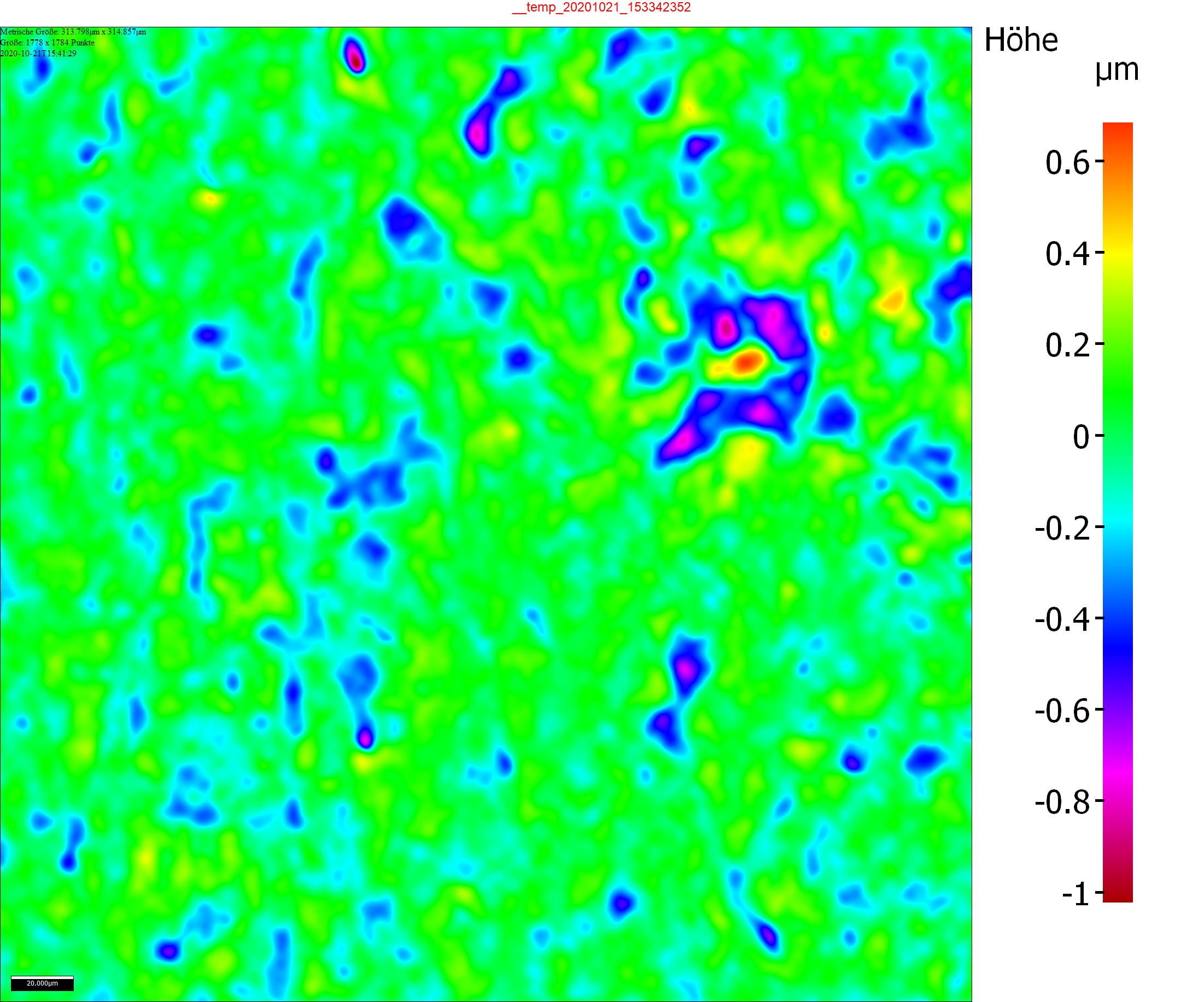

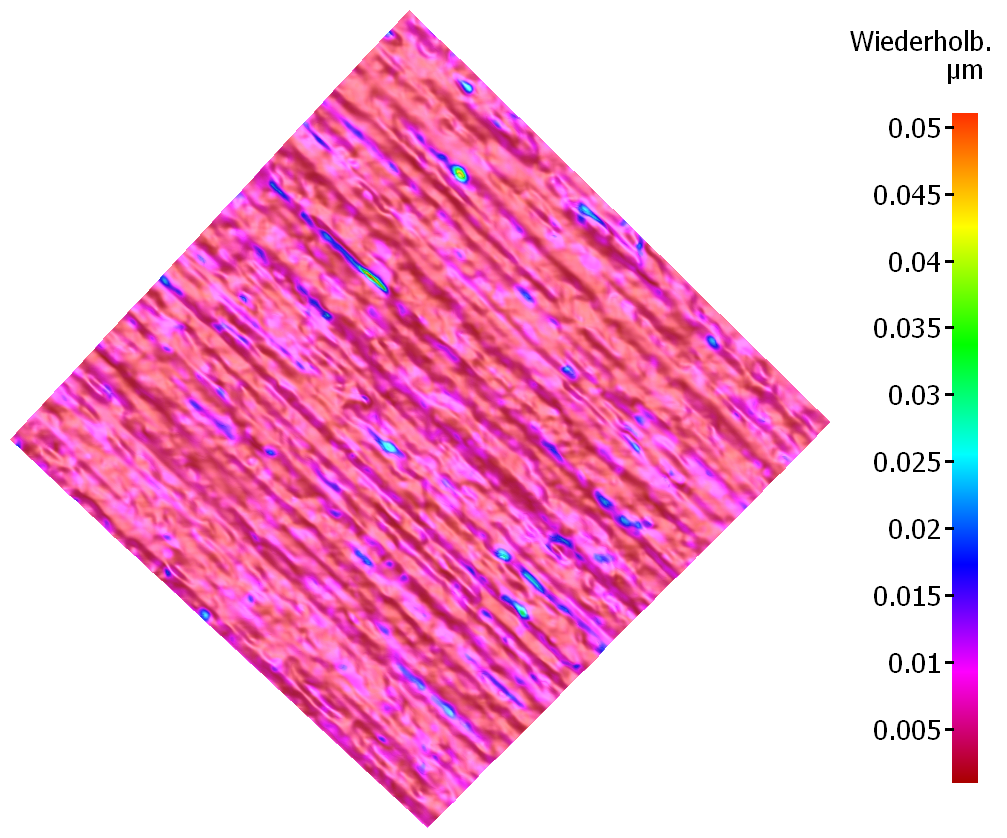

Below is a scanning electron microscope image of the stainless steel surface after electropolishing and Optimized Grind Finishing, as well as images of the surface texture roughness data and repeatability.

Easy cleaning & minimal adhesion

The Optimized Grind Finishing (OGF) process leads to a low adhesion of particles on the surfaces of the containers. This significantly improves cleaning efficiency and reduces the risk of contamination of product batches.

Reproducible surface quality

The OGF process enables reproducible surface quality. In contrast to conventional processes, in which variable factors such as manual contact pressure or the quality of abrasives play a role, the OGF process offers consistent surface quality.

Visual aesthetics and low number of errors

The stainless steel surfaces treated with the OGF process have an attractive appearance and defects in the surface structure are significantly reduced thanks to the fine and gentle removal process. This is particularly important in industries that place high demands on safety.

Improved corrosion protection

The electropolishing process not only improves the optical quality, but also results in chemical changes that lead to improved corrosion protection. This is particularly relevant for applications in chemical and pharmaceutical processes.

Reduced risk of batch contamination

The improvement in cleaning behavior through the OGF process leads to a significant reduction in residual dirt adhesion in the containers. This significantly reduces the risk of contamination between different product batches.

Applicability in critical industries

The process is seen as particularly advantageous for critical industries such as nanotechnology or biotechnology and pharmaceutical technology, where the highest purity requirements and the avoidance of contamination are of crucial importance.

Increased efficiency through minimal adhesion

Simply send an e-mail and receive the download link

Services from BOLZ INTEC

Technical advice & design

Barrel repair

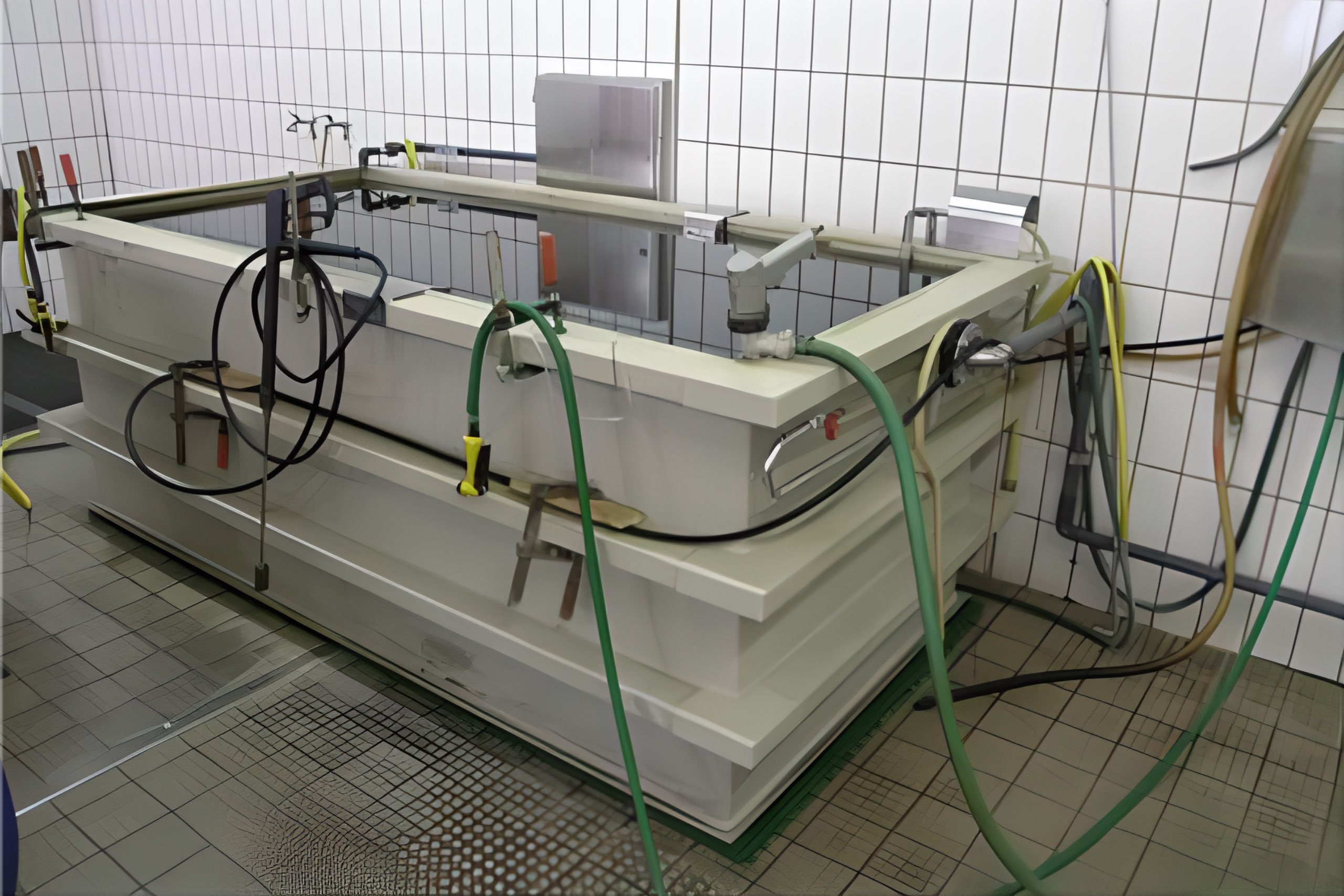

Simoflex® drum wash

Electropolishing

Why customers around the world choose our stainless steel containers

Tradition & innovation since 1919

BOLZ INTEC specializes in the manufacture of stainless steel drums, pressure vessels, agitator vessels, transport containers and transfer systems for hygiene-sensitive industries.

High vertical integration

BOLZ INTEC has acquired outstanding expertise in the machining of stainless steels and special materials such as Hastelloy. Combined with the skills and abilities of our team, this enables us to achieve maximum vertical integration. All production steps are carried out in-house. BOLZ INTEC is therefore able to react extremely flexibly to customer delivery date requests and guarantee unique quality.

Customized solutions

Our design department designs, plans and develops practical products according to our customers' requirements. These include, for example, containers for pasty substances or liquids, transport containers for UN hazardous goods, cans for the storage and transfer of active ingredients, suction hoods for dust-free container loading and much more.

One-off production & small series

BOLZ INTEC also manufactures custom-made products and small series.

Machines for perfect surfaces

Nothing in the BOLZ INTEC machine park is off the shelf. From the deep-drawing press to the electropolishing system, we work with special machines that have been developed according to our own specifications in order to meet the highest standards of quality and precision.

Traceability & reproducibility

BOLZ INTEC's QM system and our intensive testing procedures ensure the consistent quality of the stainless steel surfaces manufactured by BOLZ INTEC. In this way, we make a decisive contribution to the traceability of products in critical industries.

Trust & security

Our striving for perfect quality, state-of-the-art production methods, but also craftsmanship and know-how are the basis for the superior BOLZ INTEC quality, which means safety and reliability for our customers. It is therefore not surprising that 80% of our customers have reordered every year for the last 10 years.

Comprehensive certification

We regularly have our quality certified externally: DIN 9001:2015, DIN EN ISO 3834-2:2006-03, DIN EN ISO 115085-2/CL1. We are a specialist company according to WHG §19/1 and carry out process tests according to DIN EN ISO 15614-1, operator tests according to DIN EN 1418. BOLZ INTEC fulfills the Pressure Equipment Directive-2014-68-EU/AD-2000 HPO and employs Intern. Welding engineers (DVS/IIW 1170).

High efficiency, low costs & great economy thanks to superior stainless steel surfaces

Time savings in production

The use of stainless steel containers with optimized surfaces leads to significant time savings in the production process. By minimizing the build-up of materials, cleaning and maintenance times can be drastically reduced. This enables the containers to be reused more quickly and increases the overall efficiency of the production lines. In a production-intensive environment where time equals money, this time saving represents a significant economic advantage.

Reduced risk of production downtime

The reproducible quality of the stainless steel surfaces and the reduced number of defects minimize the risk of production downtime due to surface problems. This can lead to higher overall productivity and less downtime.

Reduction of production losses

Optimizing the container surfaces also minimizes the amount of product loss. Reduced adhesion means that more of the material produced is available for its intended use and does not end up as waste. This is a particularly important factor in industries where high-quality or very expensive materials are processed.

Improvement of product quality & product safety

Contamination-free production results in a higher quality end product. This is crucial in industries with strict quality and purity requirements, such as pharmaceuticals and food production, where purity and safety are top priorities. The use of optimized stainless steel containers can therefore also lead to an improvement in brand image and customer satisfaction.

Cost savings through more efficient cleaning

In addition to saving time, optimized surfaces also lead to a reduction in the costs of cleaning processes. Less build-up means less need for cleaning agents, water and energy. There is also less wear and tear on the containers themselves, which increases their service life and reduces the need for new purchases. In the long term, these savings in operating costs can make a significant difference to a company's profitability.

Longer container service life

The improved corrosion protection provided by the electropolishing process helps to extend the service life of stainless steel containers. Customers can thus reduce their costs for replacement investments and maintenance.

Reach your goal in just a few steps

Request

Send us an e-mail, give us a call or book an appointment via Calendly. In a phone call with one of our competent contacts, we will clarify a few questions in advance using checklists and send you a non-disclosure agreement (NDA).

Test phase

Based on your objectives and specifications, you will receive drums, containers, funnels and accessories from our test center - as required - to try out and test. You can use your test equipment to verify or adapt the specifications of your request.

Offer

During a visit to your premises, our competent contact partners will advise you on clarifying any final questions, finding solutions to identified problems and defining your exact requirements. We can then start production.

The last barrel arrived last week. We received all the parts we ordered on time. Your prompt and professional support enabled us to keep to our schedule. Finally, I would like to thank you for your constructive, professional and reliable cooperation."

the customer has accepted the funnel and is very satisfied.

I wanted to thank you again for the fast processing and delivery..."

Thank you very much for this good news and please pass on our thanks to your production staff and all those involved, as it has now been possible to produce the tanks for us at very short notice. You have helped us a great deal."

Our project team looks forward to your inquiry

Do you have questions about our products and services or would you like advice from one of our competent employees?

Give us a call or send us an e-mail. We will make time for you and will be happy to call you back if you wish.

Interesting & worth knowing

1919

is the year in which BOLZ INTEC was founded

49

BOLZ INTEC has highly qualified employees with a passion for quality.

0,5

liters is the smallest drum in the world from BOLZ INTEC with the dimensions Ø120 V0.5l

20

years is the service life of a stainless steel drum from BOLZ INTEC with regular maintenance

3

times faster is the flow rate of viscous media in a drum from BOLZ INTEC with OGF finishing

4

is the time-saving factor when cleaning stainless steel drums with finishing using the OGF process from BOLZ INTEC

4

times faster flow of hyaluronic acid in a container from BOLZ INTEC with an OGF-coated surface

1963

BOLZ INTEC started with the production of round containers made of stainless steel

3.500

m2 is the production area of BOLZ INTEC

12

bar is the maximum pressure for pressure vessels from BOLZ INTEC

500

liters is the capacity of BOLZ INTEC's largest drum

0,05

Ra < 0.05 µm is the roughness of stainless steel surfaces that have been refined using the OGF process from BOLZ INTEC

News / Press articles / Dates / Trade fairs

Prof. Dr.-Ing. Arnulf Hörtnagl, lecture PharmaTechnica 2024

Ferry Boat 2024

ACHEMA 2024

Become our development partner or sales partner!

Contribute your expertise and all your experience to achieve common goals and realize innovative ideas.

- Develop and design industry-leading products, services and projects in close cooperation with BOLZ INTEC.

- Offer BOLZ INTEC's innovative and high-revenue products and services to your market, your industry and your customers.

You ask, we answer

Our stainless steel containers and appliances are used in various industries, including pharmaceuticals, chemicals, food, cosmetics, energy and environmental technology, aerospace, as well as research facilities and laboratories.

Our stainless steel containers are available in a variety of sizes and capacities to meet the individual requirements of our customers. Contact us for customized solutions.

We offer customized solutions and adapt our stainless steel containers to individual requirements, such as process parameters, volumes and special functions.

Our services include electropolishing, mechanical processing and the unique Optimized Grind Finishing (OGF) process for optimum surface quality and minimal particle adhesion.

Our containers meet the strict hygiene standards of the EHEDG (European Hygienic Engineering & Design Group) and are therefore ideal for use in hygiene-sensitive sectors.

Our experienced team offers comprehensive advice and support for the seamless integration of our stainless steel containers and appliances into existing production processes.

The maintenance requirements for our stainless steel containers and appliances are minimal. Regular inspections and, if necessary, cleaning are sufficient. Our stainless steel tanks are durable and robust and, if the worst comes to the worst, we offer our customers repair services.

Our optimized stainless steel containers offer better cleaning properties, lower particle adhesion and meet the highest hygiene and cleanliness standards.

Our stainless steel containers are resistant to aggressive chemicals and are perfect for safe storage and transportation in the chemical industry.

The surface finish has a decisive influence on the chemical and physical properties of stainless steels. In hygiene-sensitive sectors such as the pharmaceutical, cosmetics and food industries, technical terms such as EHDG or hygienic design are becoming increasingly important. The background to this is that operators want to avoid the carry-over of particles and the associated contamination of their batches as far as possible. One of the decisive factors here is the cleaning behavior of surfaces and the associated adhesion behavior of particles.

BOLZ INTEC, a long-standing producer of containers and special constructions made of chrome-nickel steels, has asked itself precisely these questions and has investigated the properties of surfaces in several years of research work in cooperation with the University of Constance. In addition to the usual roughness profile of surfaces, which is currently used as the main feature when describing surface quality, attention was paid to other factors such as their final surface energy and examined in more detail.

The current state of the art is the assessment of surfaces using non-destructive testing, such as roughness depth measurement in conjunction with optical testing. However, in addition to these, there are other criteria that should not be ignored. Among other things, the way in which the surface is finished should be considered. It has been found that different grinding methods show different adhesion behavior in the final assessment of the surface, although the Ra value of both surfaces is the same. This means that the way in which the material is removed plays an important role here. As an experiment, the container was ground with an automated grinding process over a long period of time, in contrast to the usual manual grinding. This fine removal over a longer period of time resulted in less adhesion and therefore better cleaning. In the further course of the investigation, this was referred to as the final surface energy.

BOLZ INTEC has made use of the knowledge gained from the research cooperation with the University of Constance and developed a process in which the low and constant removal of the stainless steel surface is achieved semi-automatically over a long period of time. The process is called Optimized Grind Finishing or OGF process. The removal in the container is achieved with geometrically indeterminate grinding wheels that move inside the container. The major advantage of the OGF process is that, in addition to its outstanding quality, the surface is reproducible. The result is independent of undefined variables, such as the manual contact pressure during conventional grinding by an employee or the quality of the abrasives.

In the course of the investigations in cooperation with the University of Constance, BOLZ INTEC has further refined stainless steel surfaces refined using the OGF process and subjected them to an electropolishing process. In this process, the peaks in the surface structure are further removed, which, in addition to optical advantages, also brings chemical changes, such as improved corrosion protection through a reinforced passive layer. In the final assessment of the study, the improved cleaning behavior was demonstrated with the help of a test based on VDA19.1 (March 2015)/ISO16232 (December 2018). The OGF process drastically reduces residual dirt adhesion in containers and thus offers the operator the added value of significantly reducing the risk of contamination of two batches.

With the help of research, BOLZ INTEC has generated a surface whose roughness profile and optical assessment can be produced with repeat accuracy. In addition, this surface has advantages over the reference model in terms of cleaning. This added value can be decisive, especially for critical, very valuable or very fine particles. Examples include industries such as nanotechnology, biotechnology and pharmaceutical technology or all others where batch purity and the avoidance of contamination is a decisive factor in production.

Do you have questions or are you looking for advice?

Simply book a 30-minute initial consultation with us via Calendly.