Neuheiten von BOLZ INTEC

Industry-leading innovations in stainless steel for pharmaceuticals, specialty chemicals & cosmetics

- Contamination-free production: Stainless steel surfaces from BOLZ INTEC are optimized for industries with the highest demands on hygiene and cleanliness.

- Reproducible product quality: Stainless steel surfaces from BOLZ INTEC are flawless and reduce the risk of production downtime & product recalls.

- Compliance with the highest standards: Stainless steel surfaces from BOLZ INTEC guarantee compliance with GMP and EHEDG standards.

Patent für OGF-Verfahren erteilt

Am 27. März 2025 wurde der BOLZ INTEC GmbH vom Deutschen Patent- und Markenamt das Patent 10 2020 129 779 für das Optimized Grind Finishing®-Verfahren (OGF) erteilt. Das gemeinsam mit der Hochschule Konstanz entwickelte Verfahren markiert einen bedeutenden Fortschritt in der Oberflächenbearbeitung von Edelstahlbehältern – insbesondere dort, wo es auf höchste Sauberkeit, Reinigbarkeit und Partikelfreiheit ankommt. Ziel des OGF-Verfahrens ist es, durch einen präzise kontrollierten Schleifprozess eine extrem glatte, hydrophobe Oberfläche mit sehr niedriger Rauheit zu erzeugen. Dies reduziert nicht nur die Partikelanhaftung signifikant, sondern erleichtert auch die Reinigung und steigert die Korrosionsbeständigkeit durch die Entfernung der unerwünschten Beilby-Schicht.

Die Ergebnisse der Zusammenarbeit mit der Hochschule Konstanz bestätigen: OGF ermöglicht eine reproduzierbare, gleichmäßige Oberflächenqualität, die herkömmliche Schleif- und Poliermethoden deutlich übertrifft. Besonders für Unternehmen aus der Pharma- und Chemieindustrie sowie der Lebensmittelbranche bedeutet das Verfahren einen klaren Mehrwert – sowohl hygienisch als auch wirtschaftlich. Mit der Patentierung des OGF-Verfahrens bekräftigt BOLZ INTEC seinen Anspruch, technologisch führend in der Herstellung und Veredelung hochpräziser Edelstahlbehälter und -systeme zu sein. Weitere Informationen finden Sie auf der Seite zum

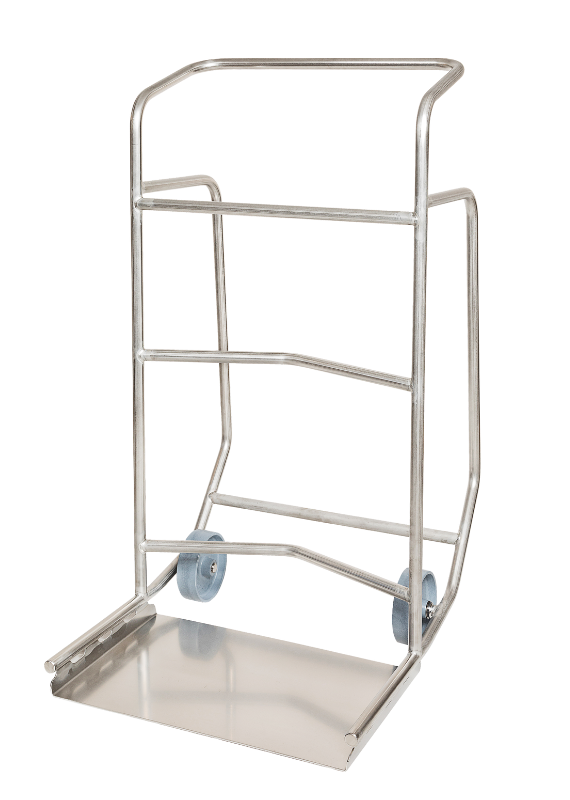

Cleanroom-compatible drum tipper in accordance with EHEDG

The cleanroom-compatible drum tipper in accordance with EHEDG offers numerous advantages: It enables the residual emptying of flowable materials as well as cleaning by tipping, protects employees from carrying heavy loads and enables easy cleaning thanks to its design features without interfering edges.

With a load capacity of up to 100 kg and a sturdy 3 mm stainless steel tube construction made of 1.4301, it effortlessly overcomes small uneven floors, inclines, slopes and steps. No additional transport vehicle is required and maximum safety is guaranteed, as the drum remains stable on the drum tipper even without being secured.

The drum tipper is cleanroom-compatible, optionally electropolished and suitable for V200/D600 and V400/D710 drums. It is also available with electrically conductive castors.

Cleanroom-compatible drum stand in GMP design

The cleanroom-compatible drum stand in GMP design offers a number of advantages: It ensures maximum safety thanks to its hygienic design (EHEDG) in accordance with Guideline 9 without dead spaces, a stable construction made of 2 mm stainless steel and the use of high-quality stainless steel (1.4404/AISI316L) with a load capacity of up to 100 kg.

In addition, it offers ergonomic handling without obstructive edges, maximum safety thanks to the drum's stable position even without fastening, as well as resource conservation thanks to the emptying of residual flowable materials and easier cleaning.

The extras include adaptation to all drum sizes with diameters from 315 to 770 mm, provision of documentation and 3.1 certificate, optional electropolishing and laser marking on request.

Barrel opener in GMP design

The drum opener in GMP design from BOLZ INTEC GmbH offers a number of advantages for safety and handling. It has a hygienic design (EHEDG) without dead spaces, is autoclavable and also suitable for clean rooms.

The risk of injury when opening and closing the drums is minimized and handling is safe.

The drum opener is suitable for all BOLZ INTEC drum sizes with diameters from 315 to 770 mm and is made of high-quality stainless steel 1.4404/AISI316L.

Opening and closing the clamping rings requires little effort, and it is also available with an electropolished surface. It also offers documentation 3.1 and can be laser-marked on request.

The BOLZ-BFM® drum

The BOLZ-BFM® drum offers a number of advantages: Ensuring maximum safety through leakage protection and dust-tightness, the ability to monitor product flow, adhesion behavior and fill level control during operation, and easy management of product jams in the event of malfunctions.

It is up to 60 % lighter than conventional stainless steel drums and enables tool-free, safe and quick assembly. Thanks to its modularity, it can be adapted to different drum diameters (400, 450 and 600 mm) and can be combined for coordinated filling, storage and emptying. It can also be used with adapters for existing lidded drums and Tri-Clamps and uses transparent, temperature-resistant, abrasion-resistant polyether-based polyurethane.

It meets hygiene standards (EHEDG), GMP standard and is made of stainless steel 1.4404, is ATEX-certified and complies with food regulations in accordance with Regulation (EU) 10/2011.

Fassroller & Fasswagen für einfaches Handling im hygienischen Bereich

The drum rollers and trolleys for easy handling in hygienic areas offer numerous advantages: they are constructed in accordance with Hygienic Design without dead spaces, are made of sturdy 1.4301/AISI304 stainless steel and can bear loads of up to approx. 300 kg.

They are suitable for drums with a diameter of 400 to 710 mm and are easy to clean. Each drum roller and trolley is equipped with 2 castors with brakes and can also be supplied with electrically conductive castors. An electropolished surface is possible.

Ergonomic working is made possible by not having to lift and carry the drums. Documentation 2.1 is also provided.

Patent-Fass Best Cost Drum®

With the Best Cost Drum®, BOLZ INTEC has developed a price-optimized stainless steel drum with a flat bottom that is suitable for both single-use applications and as dedicated equipment.

Made from thin-walled stainless steel, it is available in versions with a diameter of 450 or 560 mm and a volume of 100 or 200 liters. Thanks to its modular design, it enables different closure variants, such as lidded and bung drums, and impresses with its high stability.

The Best Cost Drum® not only offers a solution for multiple use, but also for single use of basic and active ingredients with high purity standards by eliminating the need for cleaning. This saves time and costs. It therefore meets the economic requirements of the pharmaceutical industry and is integrated directly into the recycling process after use, thus contributing to environmental protection.

The Optimized Grind Finishing® process (OGF)

In the pharmaceutical, chemical and food processing industries, minimizing build-up in containers is a critical factor for efficiency and quality. The build-up of substances on the inside walls of containers can lead to increased cleaning effort, product losses and contamination. This costs money and ties up resources. Especially in industries where EHEDG (European Hygienic Engineering & Design Group) certification and hygienic design are becoming increasingly important, minimizing adhesion has become a critical factor.

Research carried out by BOLZ INTEC in cooperation with the University of Constance has shown that the way in which stainless steel surfaces are removed plays a key role in minimizing adhesion. Different grinding methods result in different adhesion behavior, despite the same Ra values, and the OGF process from BOLZ INTEC leads to a lower adhesion of particles.

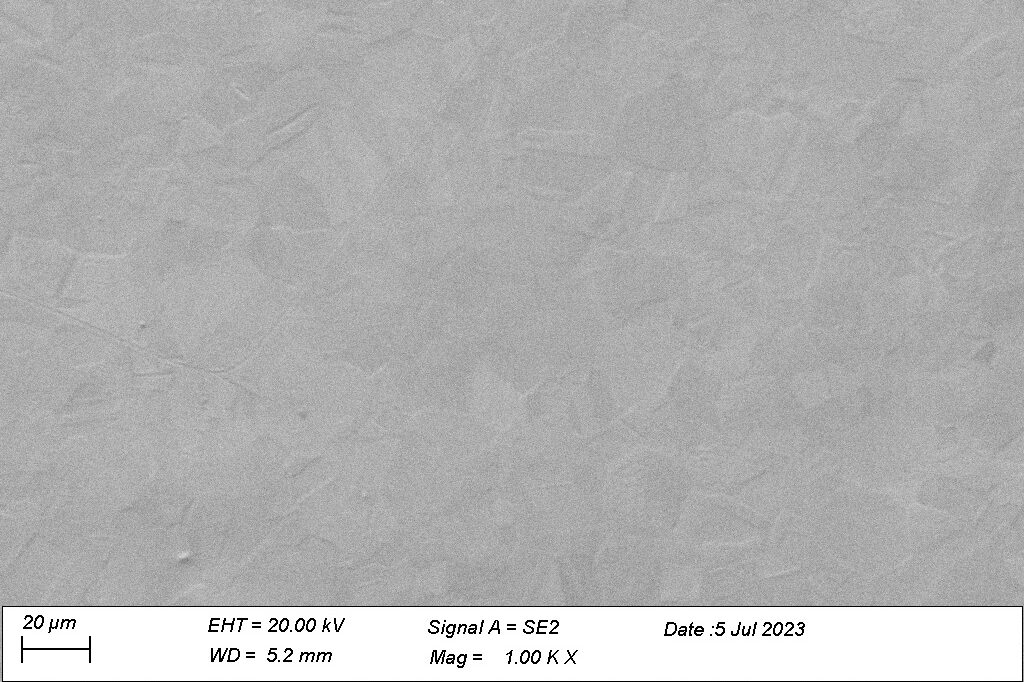

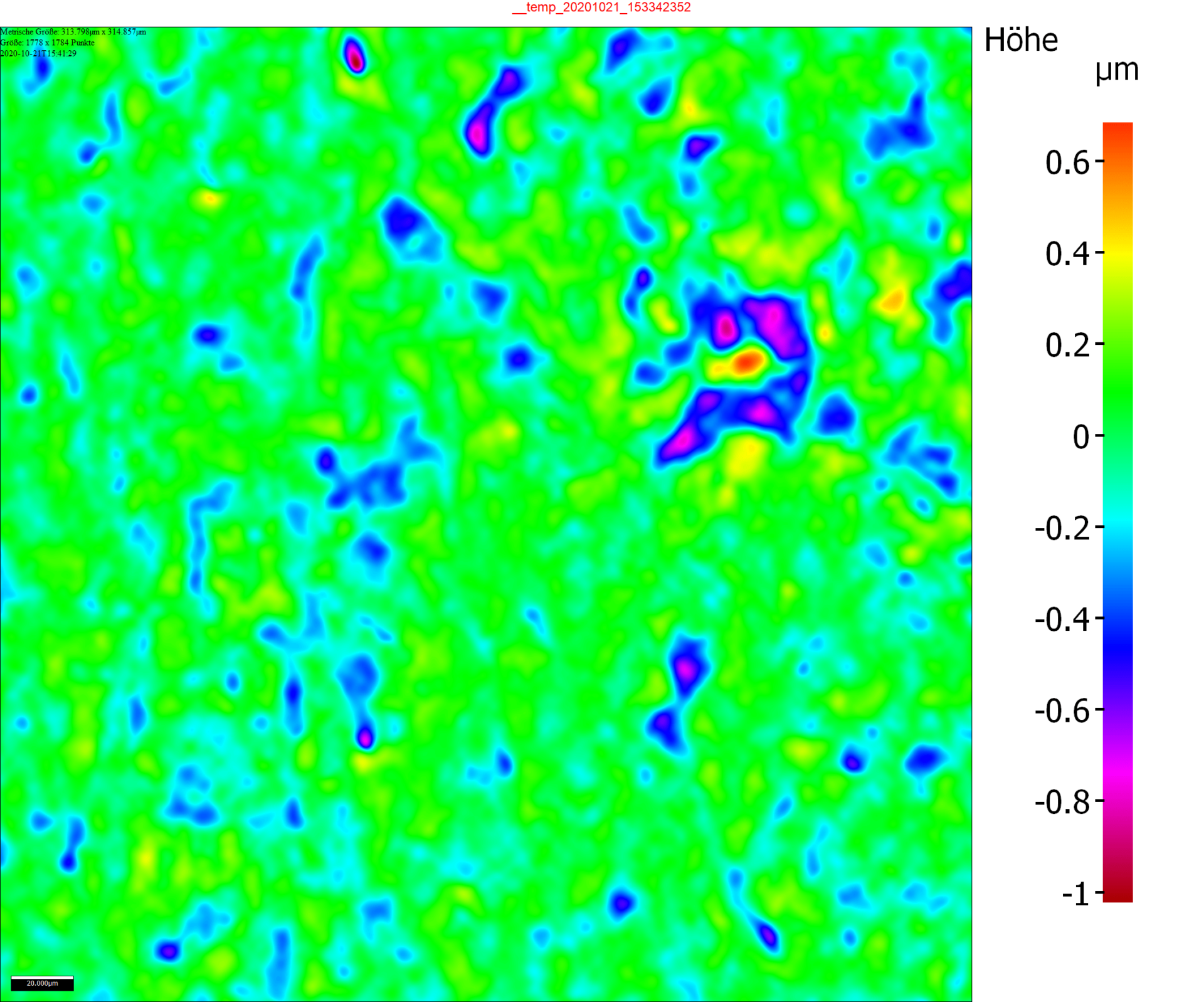

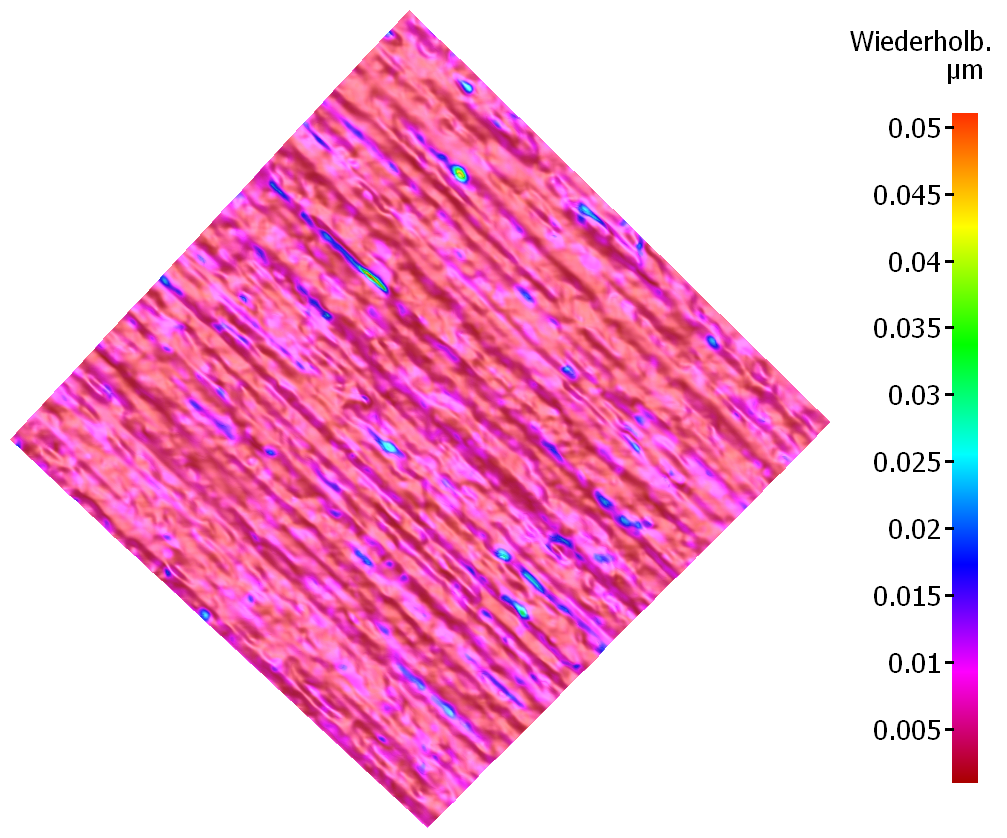

Below is a scanning electron microscope image of the stainless steel surface after electropolishing and Optimized Grind Finishing®, as well as images of the surface texture roughness data and repeatability.

Easy cleaning & minimal adhesion

The Optimized Grind Finishing (OGF) process leads to a low adhesion of particles on the surfaces of the containers. This significantly improves cleaning efficiency and reduces the risk of contamination of product batches.

Reproducible surface quality

The OGF process enables reproducible surface quality. In contrast to conventional processes, in which variable factors such as manual contact pressure or the quality of abrasives play a role, the OGF process offers consistent surface quality.

Visual aesthetics and low number of errors

The stainless steel surfaces treated with the OGF process have an attractive appearance and defects in the surface structure are significantly reduced thanks to the fine and gentle removal process. This is particularly important in industries that place high demands on safety.

Improved corrosion protection

The electropolishing process not only improves the optical quality, but also results in chemical changes that lead to improved corrosion protection. This is particularly relevant for applications in chemical and pharmaceutical processes.

Reduced risk of batch contamination

The improvement in cleaning behavior through the OGF process leads to a significant reduction in residual dirt adhesion in the containers. This significantly reduces the risk of contamination between different product batches.

Applicability in critical industries

The process is seen as particularly advantageous for critical industries such as nanotechnology or biotechnology and pharmaceutical technology, where the highest purity requirements and the avoidance of contamination are of crucial importance.

Increased efficiency through minimal adhesion

Simply send an e-mail and receive the download link

Effizienzsteigerung, Kostensenkung & Return on Investment

Time savings in production

The use of stainless steel containers with optimized surfaces leads to significant time savings in the production process. By minimizing the build-up of materials, cleaning and maintenance times can be drastically reduced. This enables the containers to be reused more quickly and increases the overall efficiency of the production lines. In a production-intensive environment where time equals money, this time saving represents a significant economic advantage.

Reduced risk of production downtime

The reproducible quality of the stainless steel surfaces and the reduced number of defects minimize the risk of production downtime due to surface problems. This can lead to higher overall productivity and less downtime.

Reduction of production losses

Optimizing the container surfaces also minimizes the amount of product loss. Reduced adhesion means that more of the material produced is available for its intended use and does not end up as waste. This is a particularly important factor in industries where high-quality or very expensive materials are processed.

Improvement of product quality & product safety

Contamination-free production results in a higher quality end product. This is crucial in industries with strict quality and purity requirements, such as pharmaceuticals and food production, where purity and safety are top priorities. The use of optimized stainless steel containers can therefore also lead to improved brand image and customer satisfaction. We ensure the quality of our containers through our QM officer and stringent production processes. You will receive the corresponding documentation for each of our stainless steel drums.

Cost reduction through efficient cleaning & barrel maintenance

In addition to saving time, optimized surfaces also lead to a reduction in the costs of cleaning processes. Less build-up means less need for cleaning agents, water and energy. There is also less wear and tear on the containers themselves, which increases their service life and reduces the need for new purchases. In the long term, these savings in operating costs can make a significant difference to a company's profitability.

Longer container service life & positive eco-balance

The improved corrosion protection provided by the electropolishing process helps to extend the service life of stainless steel containers. Customers can thus reduce their costs for replacement investments and maintenance.

Warum sich Kunden weltweit für unsere Behälter & Konstruktionen aus Edelstahl entscheiden

Tradition & innovation since 1919

BOLZ INTEC specializes in the manufacture of stainless steel drums, pressure vessels, agitator vessels, transport containers and transfer systems for hygiene-sensitive industries.

High vertical integration

BOLZ INTEC has acquired outstanding expertise in the machining of stainless steels and special materials such as Hastelloy. Combined with the skills and abilities of our team, this enables us to achieve maximum vertical integration. All production steps are carried out in-house. BOLZ INTEC is therefore able to react extremely flexibly to customer delivery date requests and guarantee unique quality.

Customized solutions

Our design department designs, plans and develops practical products according to our customers' requirements. These include, for example, containers for pasty substances or liquids, transport containers for UN hazardous goods, cans for the storage and transfer of active ingredients, suction hoods for dust-free container loading and much more.

One-off production & small series

BOLZ INTEC also manufactures custom-made products and small series.

Machines for perfect surfaces

Nothing in the BOLZ INTEC machine park is off the shelf. From the deep-drawing press to the electropolishing system, we work with special machines that have been developed according to our own specifications in order to meet the highest standards of quality and precision.

Traceability & reproducibility

BOLZ INTEC's QM system and our intensive testing procedures ensure the consistent quality of the stainless steel surfaces manufactured by BOLZ INTEC. In this way, we make a decisive contribution to the traceability of products in critical industries.

Trust & security

Our striving for perfect quality, state-of-the-art production methods, but also craftsmanship and know-how are the basis for the superior BOLZ INTEC quality, which means safety and reliability for our customers. It is therefore not surprising that 80% of our customers have reordered every year for the last 10 years.

Comprehensive certification

We regularly have our quality certified externally: DIN 9001:2015, DIN EN ISO 3834-2:2006-03, DIN EN ISO 115085-2/CL1. We are a specialist company according to WHG §19/1 and carry out process tests according to DIN EN ISO 15614-1, operator tests according to DIN EN 1418. BOLZ INTEC fulfills the Pressure Equipment Directive-2014-68-EU/AD-2000 HPO and employs Intern. Welding engineers (DVS/IIW 1170).

Kunden aus diesen Branchen erhöhen ihre Effizienz mit Produkten & Neuheiten aus Edelstahl von BOLZ INTEC

In drei Schritten zum Ziel

Request

Send us an e-mail, give us a call or book an appointment via Calendly. In a phone call with one of our competent contacts, we will clarify a few questions in advance using checklists and send you a non-disclosure agreement (NDA).

Test phase

Based on your objectives and specifications, you will receive drums, containers, funnels and accessories from our test center - as required - to try out and test. You can use your test equipment to verify or adapt the specifications of your request.

Offer

During a visit to your premises, our competent contact partners will advise you on clarifying any final questions, finding solutions to identified problems and defining your exact requirements. We can then start production.

Our project team looks forward to your inquiry

Sie haben Fragen zu unseren Neuheiten oder anderen Produkten und Leistungen oder möchten von einem unserer kompetenten Mitarbeiter beraten werden?

Give us a call or send us an e-mail. We will make time for you and will be happy to call you back if you wish.

You ask, we answer

Sie haben Fragen zu unseren Neuheiten oder suchen Beratung?

Please do not hesitate to contact us by phone or e-mail.