Tapered stainless steel containers made to measure, for technology & industry

Qualität & Sicherheit auf ein neues Level heben durch beeindruckend niedrige Partikelanhaftung

- Outstanding pressure resistance: BOLZ INTEC containers can withstand high pressure loads and offer maximum safety.

- High corrosion resistance: BOLZ INTEC conical tanks are manufactured to withstand corrosion and chemical attack.

- Many areas of application: BOLZ INTEC conical containers are suitable for a wide range of industries and are manufactured in accordance with GMP standards and EHEDG Guideline 9.

Cone containers, cone tanks & cone bases in accordance with the requirements of GMP & EHEDG Guideline 9

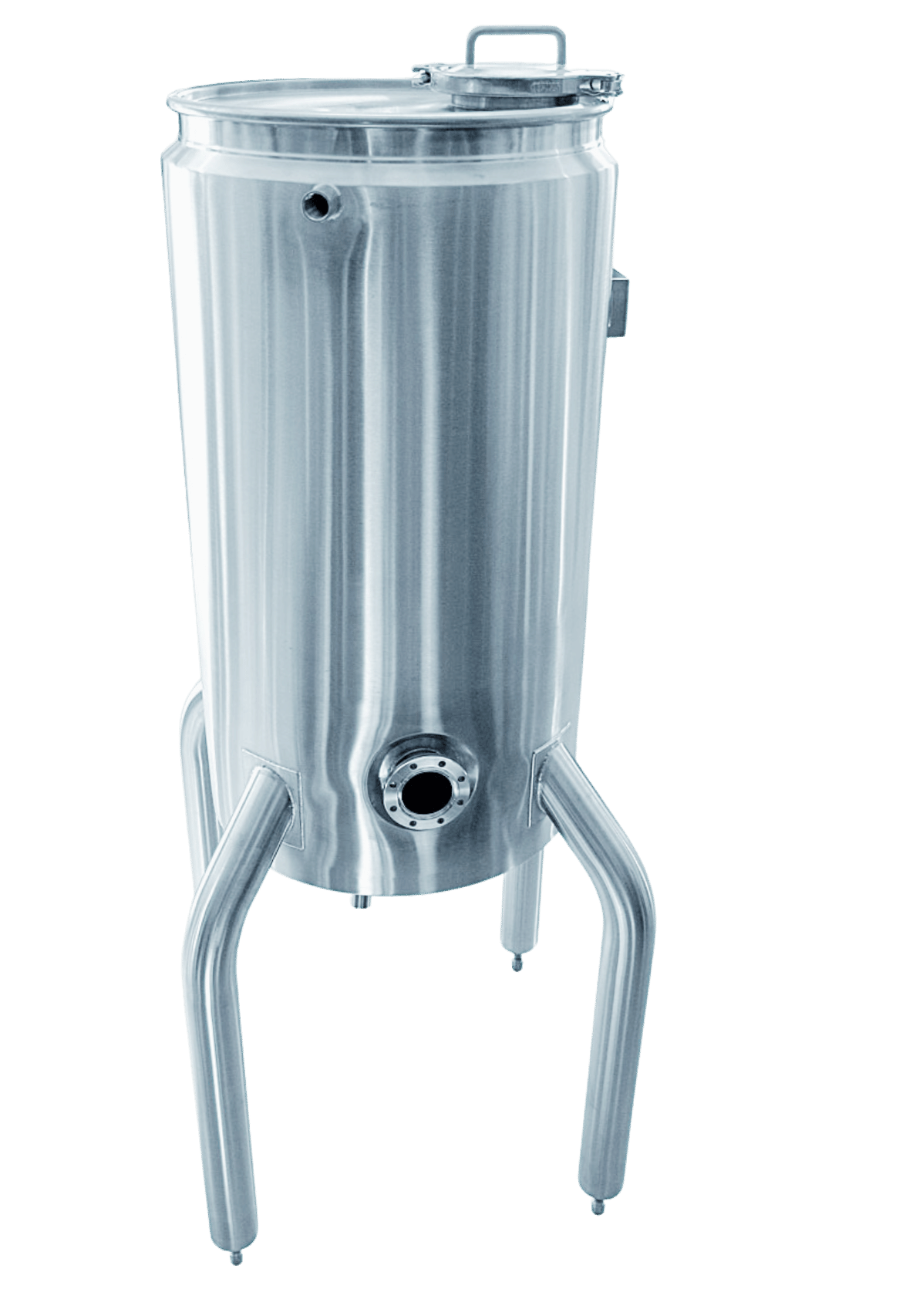

BOLZ INTEC conical containers are used to transport substances and liquids, e.g. for the pharmaceutical industry, as well as for sterile and safe storage. Each container is individually designed and produced in accordance with the latest Pressure Equipment Directive and the GMP standard. This guarantees quality and safety.

Cone containers from BOLZ INTEC are durable, easy to clean and meet the requirements of biotechnology. The design complies with EHEDG Guideline 9.

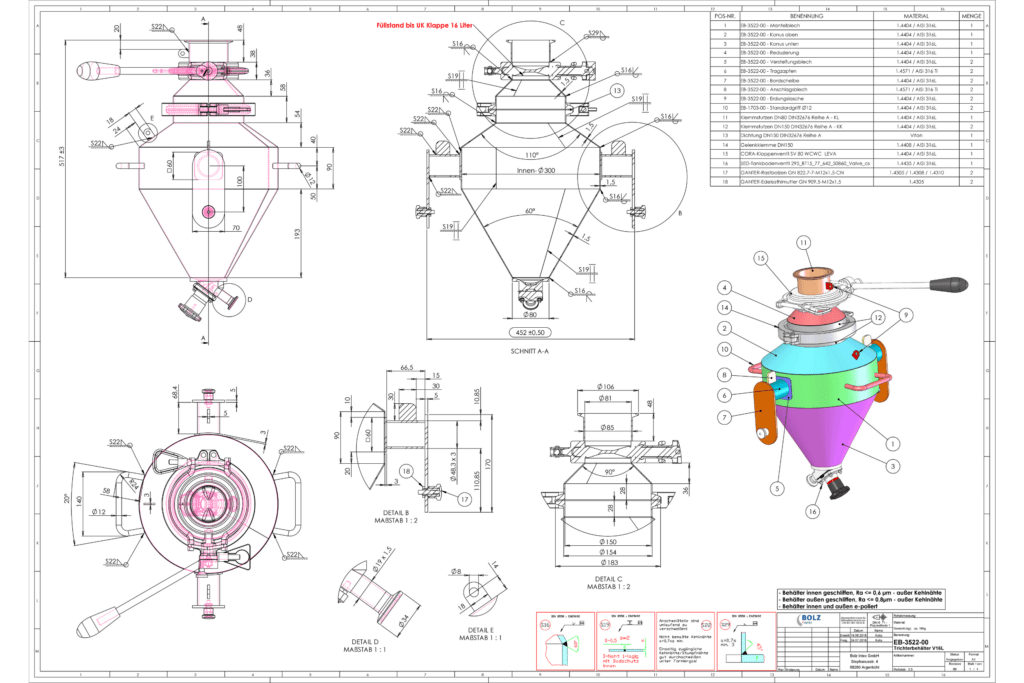

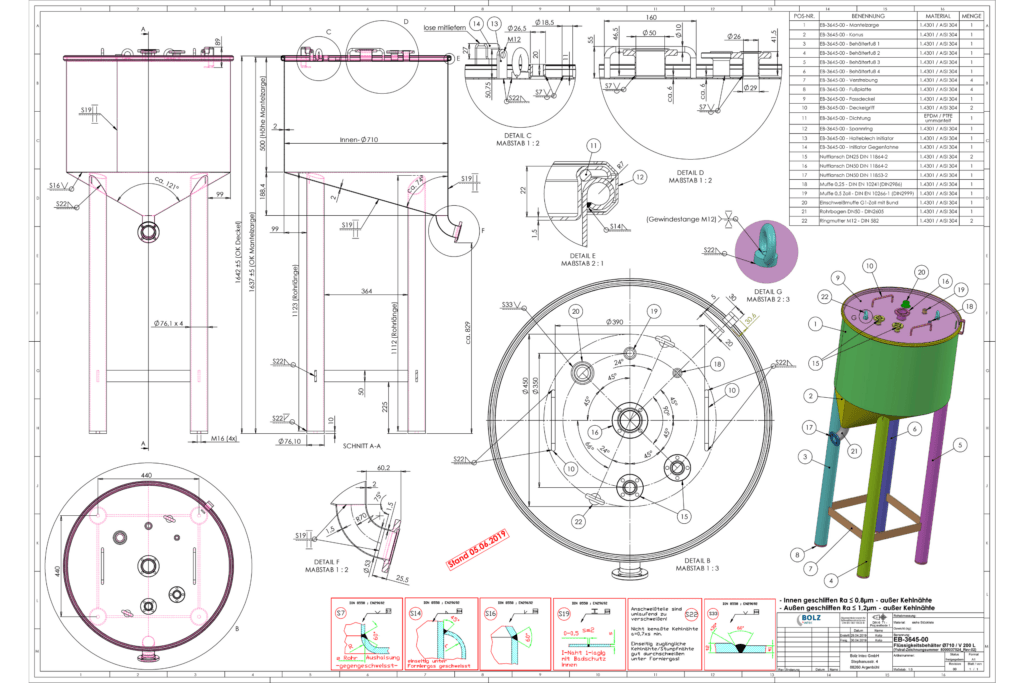

Our conical tanks are manufactured to your specific requirements, with pressures of up to 12 bar, different base and lid shapes and a range of options to meet your needs - with individual TÜV approval in accordance with Module G on request.

Cone containers from BOLZ INTEC offer the following options for individual customization

Diameter 120 mm - 900 mm

Usable volume from 0.5 to 1,000 liters

Operating pressure

-1 / +12 bar

Internal surface Ra ' 0.25 µm

External surface Ra ' 1.2 µm

single-wall / single-wall insulated

Double jacket / double jacket insulated

with heating ducts / insulated with heating ducts

Dished / conical / flat bottom

Dished / conical / flat bottom insulated

Raised floor / raised floor insulated

Heating jacket / cooling jacket

Insulating jacket / Armaflex® insulating material

Handles

Feet with base plate / on spherical caps / castors

Pratzen / standing ring / lying

Frame / mobile frame / skid / forklift mount

Various sealing materials

Tri-Clamp connecting piece to DIN 32676

Dairy pipe fitting to DIN 11851

Aseptic nozzle

Socket DIN 11864 / 11851, Ingold, NA Connect, Varivent

Hinge

Zimmerlin® pressure dome cover

Sight glass round / lengthwise

Manhole / Handhole

Apparatus flange connections

Baffle

Various agitators

Various bottom outlet valves

Various diaphragm valves

Pipework with systems

Immersion tube for product removal

Safety valve Pressure gauge

Various outlet variants

Individual funnel angles

Process control

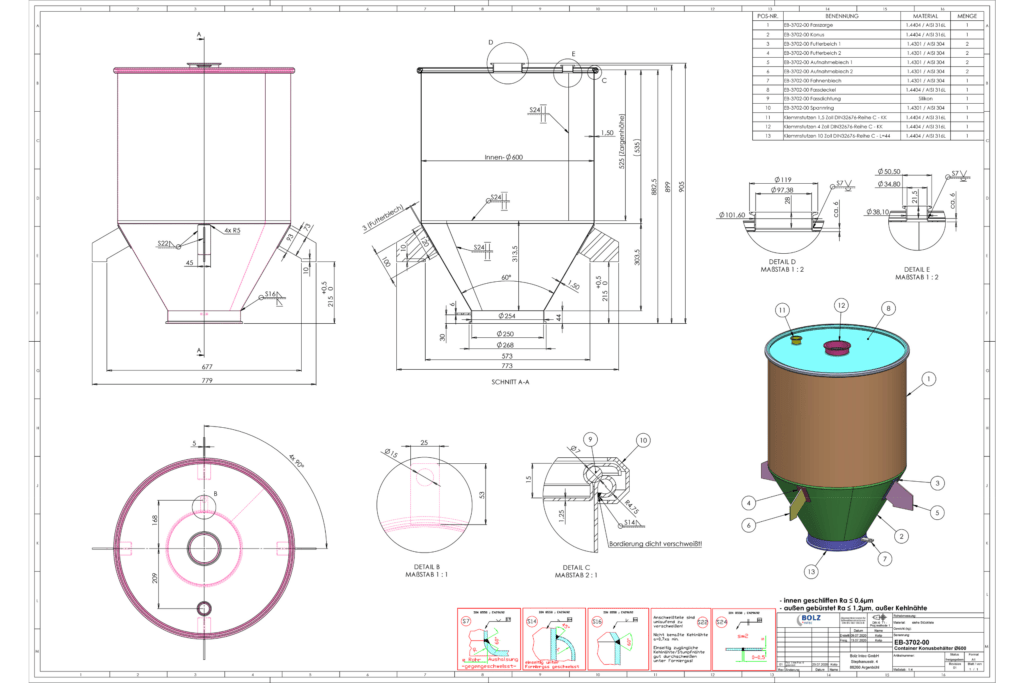

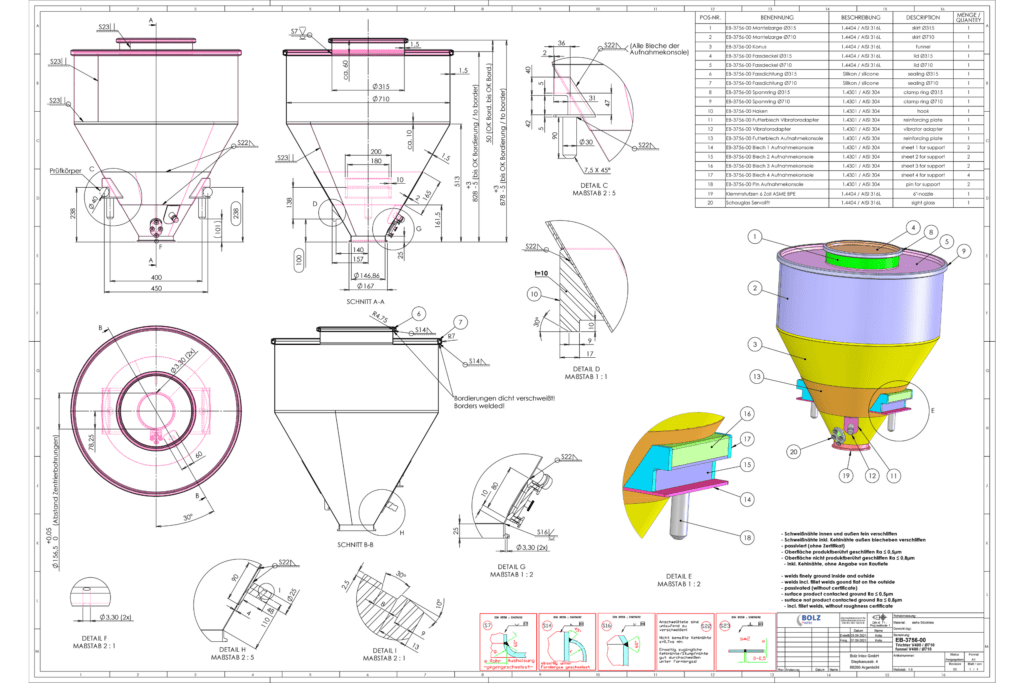

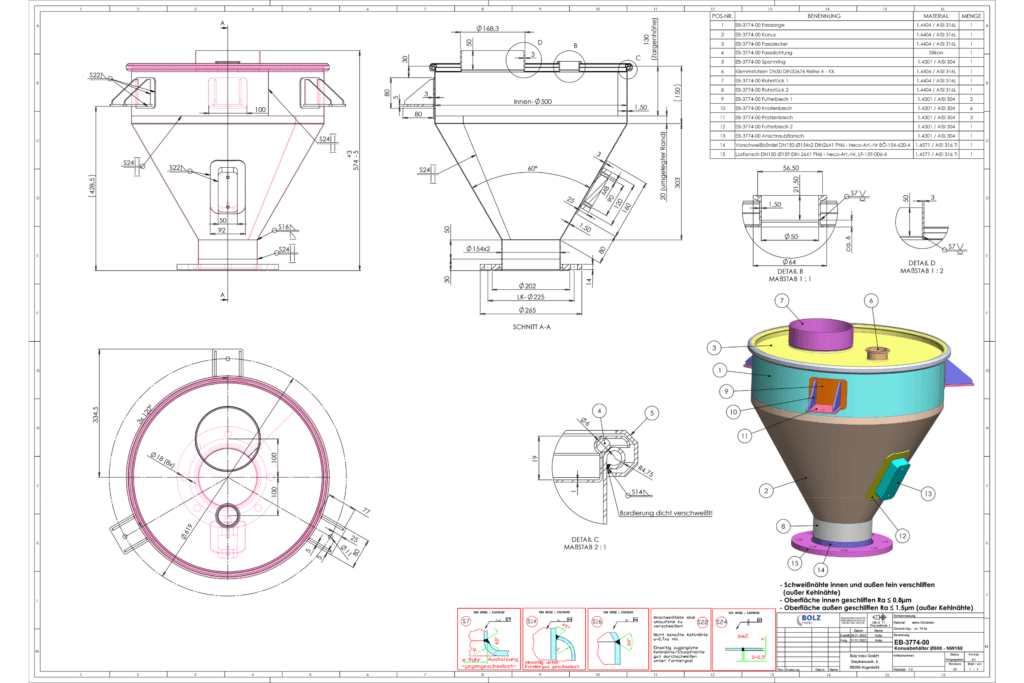

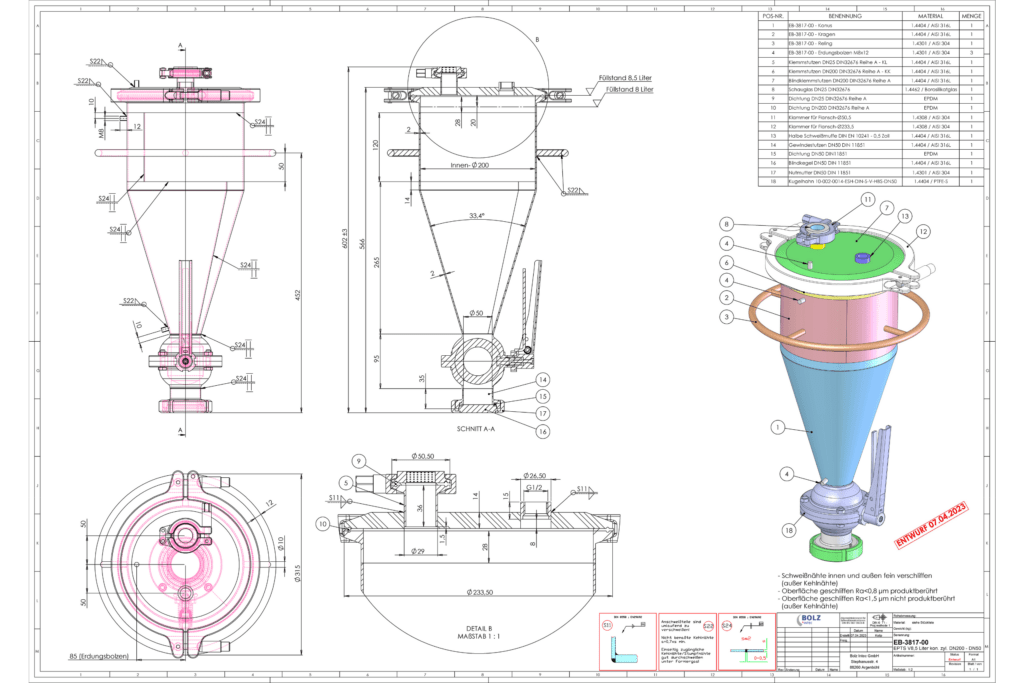

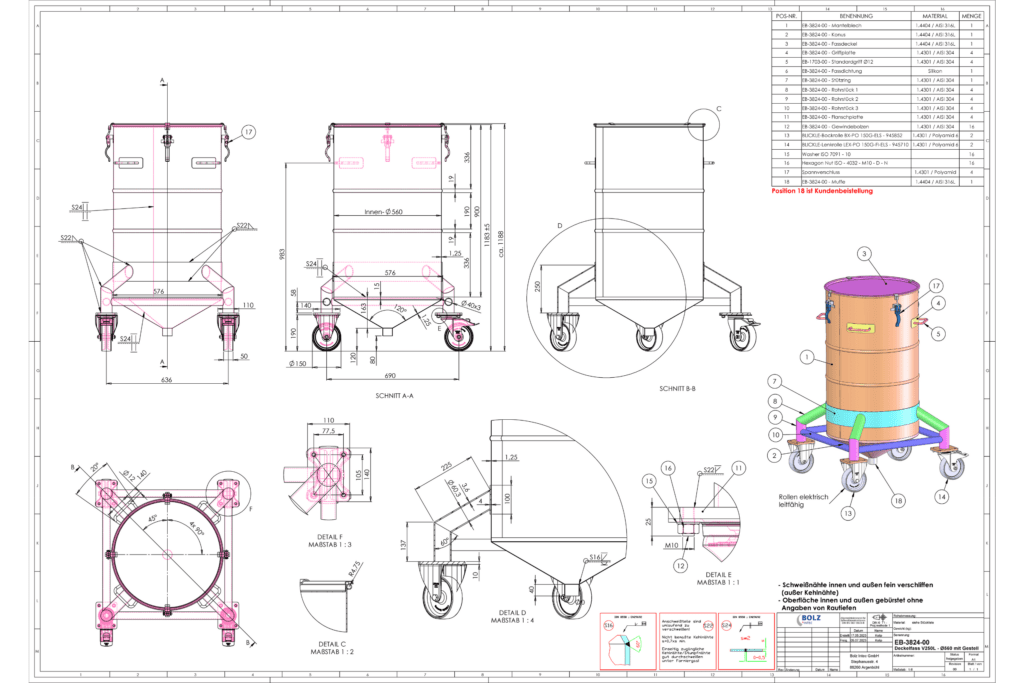

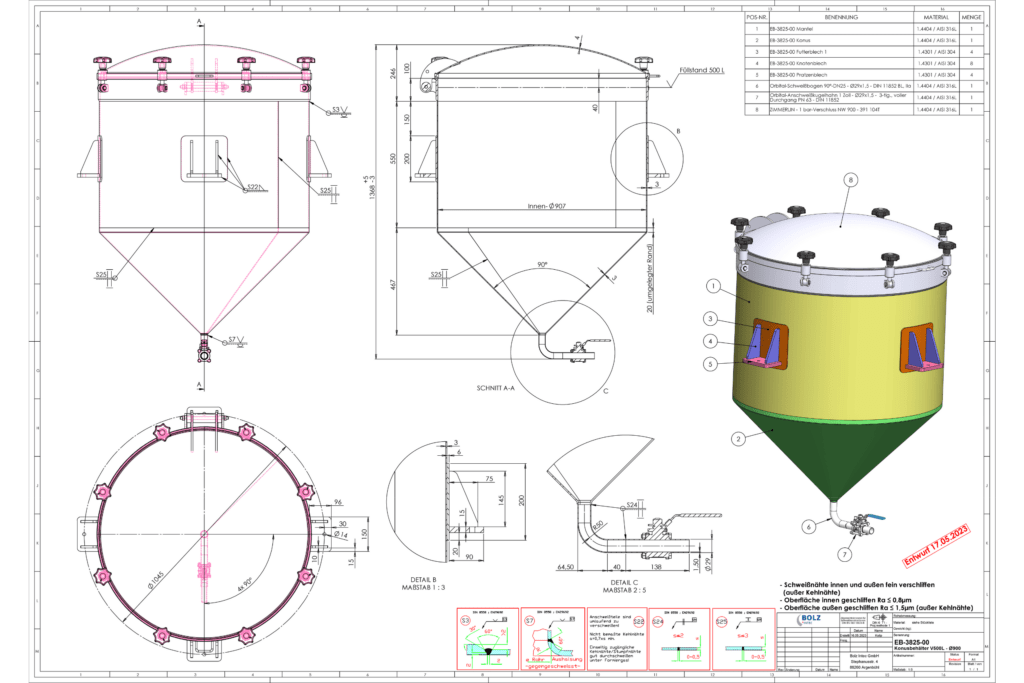

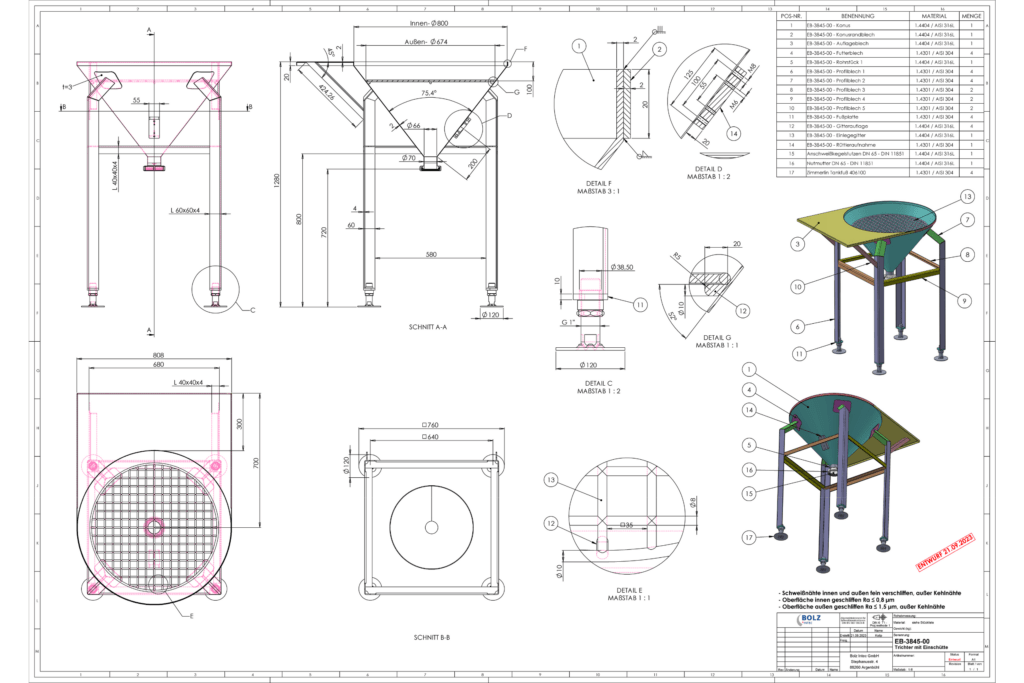

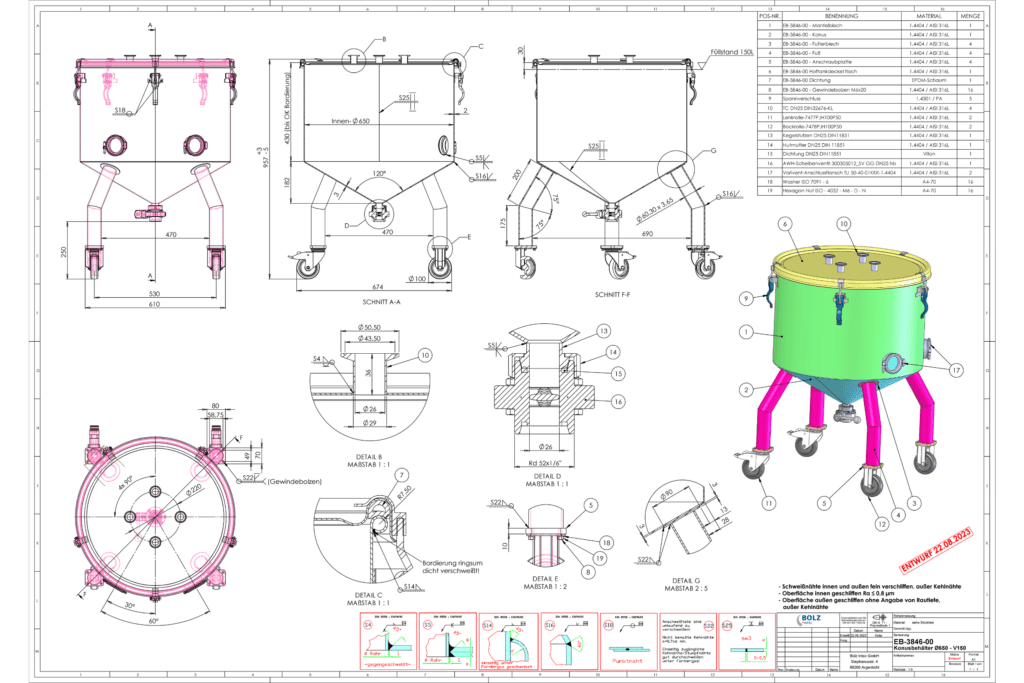

Stainless steel conical containers - examples

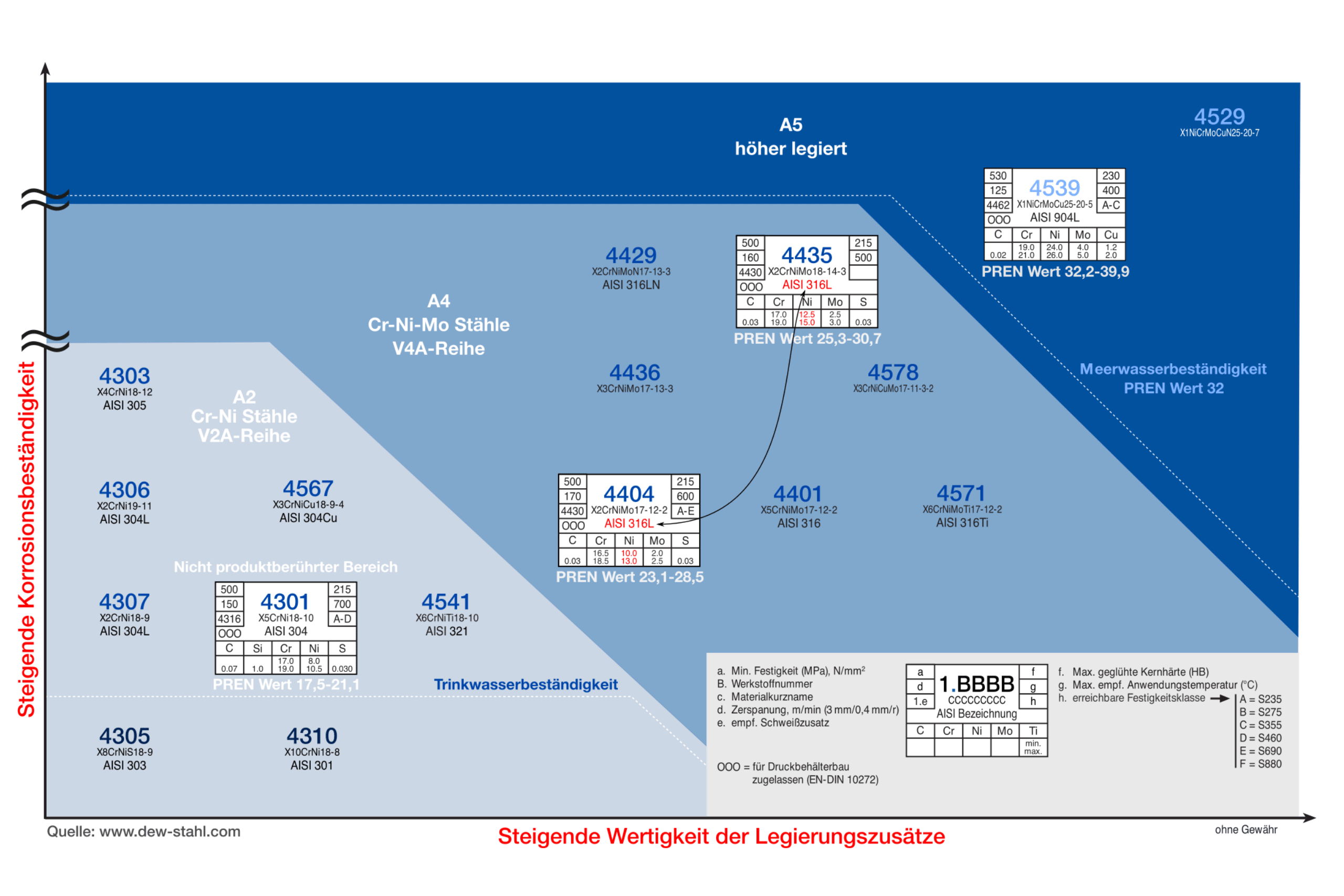

Materials for conical containers

1.4301 (AISI 304)

Corrosion-resistant austenitic steel, versatile, good weldability, suitable for chemical and food applications.

1.4404 (AISI 316L)

Austenitic steel with added molybdenum for high corrosion resistance and good weldability, versatile in use.

1.4435 (AISI 316L)

Austenitic steel with increased molybdenum content and low ferrite content (' 3 %) for improved corrosion resistance and higher resistance to pitting.

1.4539 (AISI 904L)

Heat-resistant, high-alloy steel with increased chromium and nickel content, excellent resistance to acids and corrosion at high temperatures.

2.4602 Hastelloy C22

High-alloy nickel-chromium-molybdenum steel, excellent corrosion resistance to aggressive media such as acids, chlorine and oxidizing substances.

Special materials

In addition to the materials mentioned, BOLZ INTEC also processes other materials, depending on the customer's specifications and requirements.

Surfaces for conical containers

Mill finish / 2B

Standard surface after rolling, uniform smoothness and roughness for a wide range of applications.

Brushed

Matt finish thanks to brushing, increased scratch resistance, ideal for aesthetic and functional applications.

Ground up to

Ra ' 0.4 µm

Fine, even surface, especially for applications with high purity requirements and aesthetic demands.

Electropolished up to

Ra ' 0.25 µm

High-gloss finish thanks to electrochemical polishing, maximum corrosion resistance and surface cleanliness.

OGF process up to

Ra ' 0.05 µm

Optimized Grind Finishing is a process developed by BOLZ INTEC and the University of Constance for minimal particle adhesion.

The Optimized Grind Finishing® process (OGF)

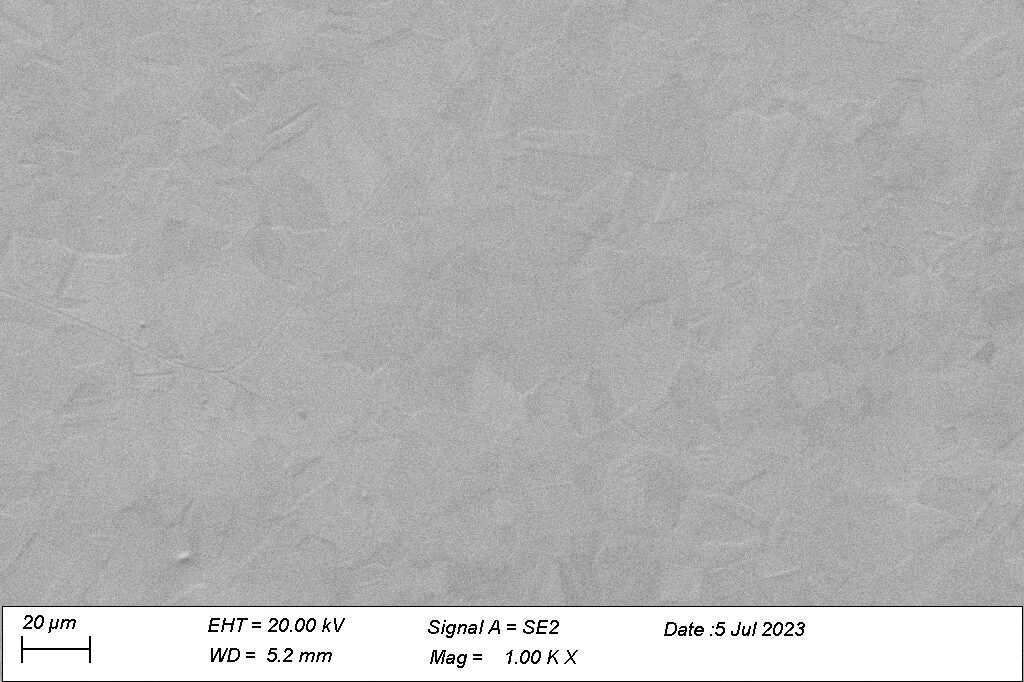

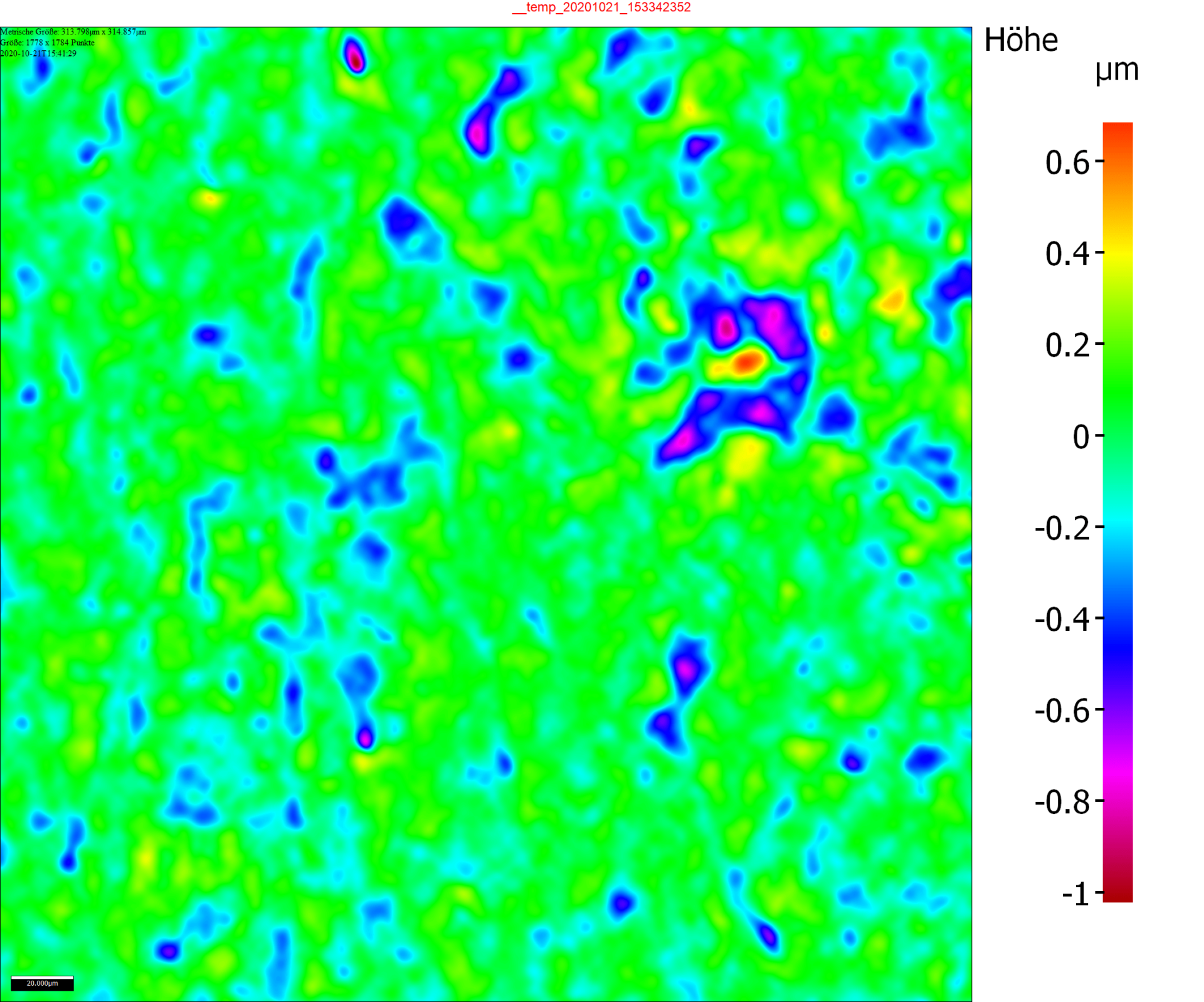

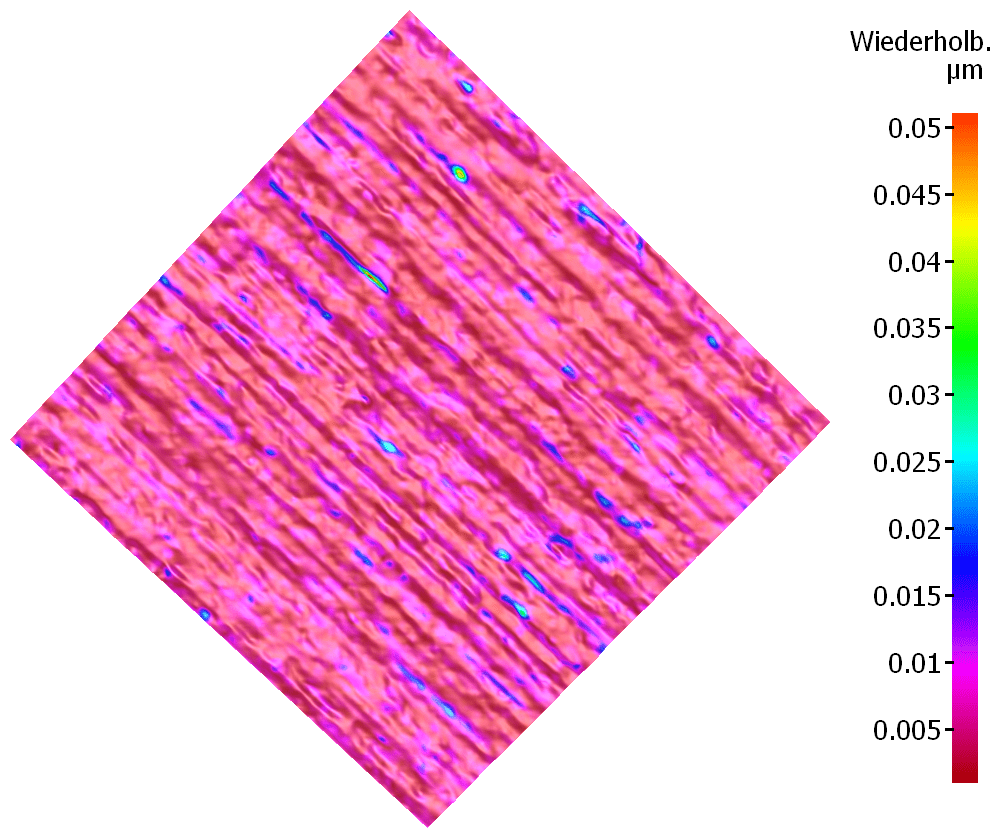

In the pharmaceutical, chemical and food processing industries, minimizing build-up in containers is a critical factor for efficiency and quality. The build-up of substances on the inside walls of containers can lead to increased cleaning effort, product losses and contamination. This costs money and ties up resources. Especially in industries where EHEDG (European Hygienic Engineering & Design Group) certification and hygienic design are becoming increasingly important, minimizing adhesion has become a critical factor, and research by BOLZ INTEC in cooperation with the University of Constance has shown that the way in which stainless steel surfaces are removed plays a key role in minimizing adhesion. Different grinding methods result in different adhesion behaviour, despite the same Ra values, and the OGF process from BOLZ INTEC leads to a lower adhesion of particles. Below is a scanning electron microscope image of the stainless steel surface after electropolishing and Optimized Grind Finishing®, as well as images of the surface texture roughness data and repeatability.

Easy cleaning & minimal adhesion

The Optimized Grind Finishing (OGF) process leads to a low adhesion of particles on the surfaces of the containers. This significantly improves cleaning efficiency and reduces the risk of contamination of product batches.

Reproducible surface quality

The OGF process enables reproducible surface quality. In contrast to conventional processes, in which variable factors such as manual contact pressure or the quality of abrasives play a role, the OGF process offers consistent surface quality.

Visual aesthetics and low number of errors

The stainless steel surfaces treated with the OGF process have an attractive appearance and defects in the surface structure are significantly reduced thanks to the fine and gentle removal process. This is particularly important in industries that place high demands on safety.

Improved corrosion protection

The electropolishing process not only improves the optical quality, but also results in chemical changes that lead to improved corrosion protection. This is particularly relevant for applications in chemical and pharmaceutical processes.

Reduced risk of batch contamination

The improvement in cleaning behavior through the OGF process leads to a significant reduction in residual dirt adhesion in the containers. This significantly reduces the risk of contamination between different product batches.

Applicability in critical industries

The process is seen as particularly advantageous for critical industries such as nanotechnology or biotechnology and pharmaceutical technology, where the highest purity requirements and the avoidance of contamination are of crucial importance.

Increased efficiency through minimal adhesion

Simply send an e-mail and receive the download link

Services from BOLZ INTEC

Technical advice & design

Barrel repair

Simoflex® drum wash

Electropolishing

Why customers around the world choose our stainless steel conical containers

Tradition & innovation since 1919

BOLZ INTEC specializes in the manufacture of stainless steel drums, pressure vessels, agitator vessels, transport containers and transfer systems for hygiene-sensitive industries.

High vertical integration

BOLZ INTEC has acquired outstanding expertise in the machining of stainless steels and special materials such as Hastelloy. Combined with the skills and abilities of our team, this enables us to achieve maximum vertical integration. All production steps are carried out in-house. BOLZ INTEC is therefore able to react extremely flexibly to customer delivery date requests and guarantee unique quality.

Customized solutions

Our design department designs, plans and develops practical products according to our customers' requirements. These include, for example, containers for pasty substances or liquids, transport containers for UN hazardous goods, cans for the storage and transfer of active ingredients, suction hoods for dust-free container loading and much more.

One-off production & small series

BOLZ INTEC also manufactures custom-made products and small series.

Machines for perfect surfaces

Nothing in the BOLZ INTEC machine park is off the shelf. From the deep-drawing press to the electropolishing system, we work with special machines that have been developed according to our own specifications in order to meet the highest standards of quality and precision.

Traceability & reproducibility

BOLZ INTEC's QM system and our intensive testing procedures ensure the consistent quality of the stainless steel surfaces manufactured by BOLZ INTEC. In this way, we make a decisive contribution to the traceability of products in critical industries.

Trust & security

Our striving for perfect quality, state-of-the-art production methods, but also craftsmanship and know-how are the basis for the superior BOLZ INTEC quality, which means safety and reliability for our customers. It is therefore not surprising that 80% of our customers have reordered every year for the last 10 years.

Comprehensive certification

We regularly have our quality certified externally: DIN 9001:2015, DIN EN ISO 3834-2:2006-03, DIN EN ISO 115085-2/CL1. We are a specialist company according to WHG §19/1 and carry out process tests according to DIN EN ISO 15614-1, operator tests according to DIN EN 1418. BOLZ INTEC fulfills the Pressure Equipment Directive-2014-68-EU/AD-2000 HPO and employs Intern. Welding engineers (DVS/IIW 1170).

High efficiency, low costs & great economy

Time savings in production

The use of stainless steel containers with optimized surfaces leads to significant time savings in the production process. By minimizing the build-up of materials, cleaning and maintenance times can be drastically reduced. This enables the containers to be reused more quickly and increases the overall efficiency of the production lines. In a production-intensive environment where time equals money, this time saving represents a significant economic advantage.

Reduced risk of production downtime

The reproducible quality of the stainless steel surfaces and the reduced number of defects minimize the risk of production downtime due to surface problems. This can lead to higher overall productivity and less downtime.

Reduction of production losses

Optimizing the container surfaces also minimizes the amount of product loss. Reduced adhesion means that more of the material produced is available for its intended use and does not end up as waste. This is a particularly important factor in industries where high-quality or very expensive materials are processed.

Improvement of product quality & product safety

Contamination-free production results in a higher quality end product. This is crucial in industries with strict quality and purity requirements, such as pharmaceuticals and food production, where purity and safety are top priorities. The use of optimized stainless steel containers can therefore also lead to an improvement in brand image and customer satisfaction.

Cost savings through more efficient cleaning

In addition to saving time, optimized surfaces also lead to a reduction in the costs of cleaning processes. Less build-up means less need for cleaning agents, water and energy. There is also less wear and tear on the containers themselves, which increases their service life and reduces the need for new purchases. In the long term, these savings in operating costs can make a significant difference to a company's profitability.

Longer container service life

The improved corrosion protection provided by the electropolishing process helps to extend the service life of stainless steel containers. Customers can thus reduce their costs for replacement investments and maintenance.

Customers from these industries increase their efficiency with conical containers, conical tanks & conical bases made of stainless steel from BOLZ INTEC

Reach your goal in just a few steps

Request

Send us an e-mail, give us a call or book an appointment via Calendly. In a phone call with one of our competent contacts, we will clarify a few questions in advance using checklists and send you a non-disclosure agreement (NDA).

Test phase

Based on your objectives and specifications, you will receive drums, containers, funnels and accessories from our test center - as required - to try out and test. You can use your test equipment to verify or adapt the specifications of your request.

Offer

During a visit to your premises, our competent contact partners will advise you on clarifying any final questions, finding solutions to identified problems and defining your exact requirements. We can then start production.

Our project team looks forward to your inquiry

Sie haben Fragen zu Konusbehältern oder unseren anderen Produkten und Leistungen oder Sie möchten von einem unserer kompetenten Mitarbeiter beraten werden?

Give us a call or send us an e-mail. We will make time for you and will be happy to call you back if you wish.

You ask, we answer

Cone container, cone container, cone tank and cone base are terms that are directly related to the production of stainless steel pressure vessels, as they describe specific construction elements and designs that are used in the manufacture of such vessels.

Conical container:

A conical container is a container whose base or lid is conical, i.e. shaped like a cone. This shape enables efficient emptying of liquids or bulk materials, as the conical base guides the material towards the center, where it can flow off or be removed more easily. In stainless steel pressure vessel production, conical containers are often used to optimize emptying processes and minimize contamination.

Cone container:

A cone container is similar to a cone container, but it is a container that also has a conical base or lid. These containers are often designed for the transportation and storage of materials under pressurized conditions. Stainless steel offers ideal properties for the manufacture of such pressurized containers due to its corrosion resistance and strength.

Conical tank:

A conical tank is a tank with a conical shape, typically at the bottom. These tanks are often used in industrial applications to store liquids or gases under pressure. The conical bottom facilitates the complete emptying and cleaning of the tank. Stainless steel conical tanks are particularly common in the food, chemical and pharmaceutical industries, as stainless steel offers high resistance to chemical reactions and easy cleanability.

Cone bottom:

A cone bottom is a specific component that is integrated into the construction of pressure vessels. It is the conically shaped bottom of a container or tank. The conical bottom helps to center and completely drain the contents of the vessel, which is particularly important when the vessel is under pressure. Stainless steel conical bottoms are a preferred choice in the production of pressure vessels due to their high strength and corrosion resistance.

Conical shapes of stainless steel containers improve the efficiency of emptying and cleaning and are particularly suitable for applications where pressure vessels are required to store and transport liquids or gases safely and hygienically.

Our stainless steel containers are available in a variety of sizes and capacities to meet the individual requirements of our customers. Contact us for customized solutions.

Our services include electropolishing, mechanical processing and the unique Optimized Grind Finishing (OGF) process for optimum surface quality and minimal particle adhesion.

Our containers meet the strict hygiene standards of the EHEDG (European Hygienic Engineering & Design Group) and are therefore ideal for use in hygiene-sensitive sectors.

Unser erfahrenes Team bietet umfassende Beratung und Unterstützung bei der nahtlosen Integration unserer Konusbehälter in bestehende Produktionsprozesse.

Der Wartungsaufwand für unsere Konusbehälter ist minimal. Regelmäßige Inspektionen und gegebenenfalls Reinigungen sind ausreichend. Unsere Konusbehälter sind langlebig und robust und im Falle des Falles bieten wir unseren Kunden deren Instandsetzung an.

Our optimized stainless steel containers offer better cleaning properties, lower particle adhesion and meet the highest hygiene and cleanliness standards.

Our stainless steel containers are resistant to aggressive chemicals and are perfect for safe storage and transportation in the chemical industry.

The surface finish has a decisive influence on the chemical and physical properties of stainless steels. In hygiene-sensitive sectors such as the pharmaceutical, cosmetics and food industries, technical terms such as EHDG or hygienic design are becoming increasingly important. The background to this is that operators want to avoid the carry-over of particles and the associated contamination of their batches as far as possible. One of the decisive factors here is the cleaning behavior of surfaces and the associated adhesion behavior of particles.

BOLZ INTEC, a long-standing producer of containers and special constructions made of chrome-nickel steels, has asked itself precisely these questions and has investigated the properties of surfaces in several years of research work in cooperation with the University of Constance. In addition to the usual roughness profile of surfaces, which is currently used as the main feature when describing surface quality, attention was paid to other factors such as their final surface energy and examined in more detail.

The current state of the art is the assessment of surfaces using non-destructive testing, such as roughness depth measurement in conjunction with optical testing. However, in addition to these, there are other criteria that should not be ignored. Among other things, the way in which the surface is finished should be considered. It has been found that different grinding methods show different adhesion behavior in the final assessment of the surface, although the Ra value of both surfaces is the same. This means that the way in which the material is removed plays an important role here. As an experiment, the container was ground with an automated grinding process over a long period of time, in contrast to the usual manual grinding. This fine removal over a longer period of time resulted in less adhesion and therefore better cleaning. In the further course of the investigation, this was referred to as the final surface energy.

BOLZ INTEC has made use of the knowledge gained from the research cooperation with the University of Constance and developed a process in which the low and constant removal of the stainless steel surface is achieved semi-automatically over a long period of time. The process is called Optimized Grind Finishing or OGF process. The removal in the container is achieved with geometrically indeterminate grinding wheels that move inside the container. The major advantage of the OGF process is that, in addition to its outstanding quality, the surface is reproducible. The result is independent of undefined variables, such as the manual contact pressure during conventional grinding by an employee or the quality of the abrasives.

In the course of the investigations in cooperation with the University of Constance, BOLZ INTEC has further refined stainless steel surfaces refined using the OGF process and subjected them to an electropolishing process. In this process, the peaks in the surface structure are further removed, which, in addition to optical advantages, also brings chemical changes, such as improved corrosion protection through a reinforced passive layer. In the final assessment of the study, the improved cleaning behavior was demonstrated with the help of a test based on VDA19.1 (March 2015)/ISO16232 (December 2018). The OGF process drastically reduces residual dirt adhesion in containers and thus offers the operator the added value of significantly reducing the risk of contamination of two batches.

Photo: Galetschbach adventure trail, path through the forest @Allgäu GmbH, the urban kids I License: https://creativecommons.org/licenses/by-sa/3.0/de/

Sie haben Fragen oder suchen Beratung betreffend Konusbehälter?

Please do not hesitate to contact us by phone or e-mail.