The 150 liter stainless steel drum from BOLZ INTEC

Superior stainless steel surfaces for minimal particle adhesion & easy cleaning

- Contamination-free production: Stainless steel drums from BOLZ INTEC are perfect for industries with the highest standards of hygiene and cleanliness.

- Reproducible product quality: Stainless steel drums from BOLZ INTEC are manufactured with precision and reduce the risk of production downtime and product recalls.

- Compliance with the highest standards: Stainless steel drums from BOLZ INTEC guarantee compliance with GMP and EHEDG.

The perfectly adapted stainless steel drum for every medium

Erfahren Sie mehr über die Vorteile, die unser Edelstahlfass 150 Liter Branchen bietet, in denen die höchsten Standards an Sicherheit, Hygiene und Reinheit gefordert sind. Unsere Fässer erfüllen gezielt die strengen Anforderungen in der Pharmaindustrie, Biotechnologie, Feinchemie und Kosmetik. Selbstverständlich ist das Edelstahlfass 150 Liter auch für den Einsatz in anderen Branchen, z.B. in Reinräumen geeignet. Mit einem Edelstahlfass von BOLZ INTEC entscheiden Sie sich für bewährte Qualität, Langlebigkeit und Sicherheit.

Das Edelstahlfass 150 Liter wird aus hoch legiertem Edelstahl hergestellt, abgestimmt auf Ihr Anwendung, was ihm eine außerordentliche Vielseitigkeit, Robustheit und Langlebigkeit verleiht. Eine breite Palette an Zubehör, darunter Fassroller und Fassöffner, vereinfacht die Handhabung und gewährleistet maximale Sicherheit. Ein weiteres Highlight sind unsere Oberflächenbehandlungen: Das Optimized Grind Finishing®-Verfahren (OGF) und das Elektropolieren sorgen für eine branchenführende Oberflächengüte. Verfügbar sowohl als maßgeschneiderte Einzelanfertigung, als auch in der Serienfertigung, wird das Edelstahlfass 150 Liter genau nach Ihren individuellen Bedürfnissen angepasst.

15 of the 20 largest pharmaceutical companies worldwide are customers of BOLZ INTEC

Diese Branchen setzen auf das Edelstahlfass 150l von BOLZ INTEC

Stainless steel drums from BOLZ INTEC have the following features

10 years shelf life due to barrel repair

Stainless steel

Light & UV-resistant

Inert & odorless / tasteless

Diffusion-proof

100 % recyclable

Reusable clamping ring cover

Simple & airtight sealing

Seals with FDA approval

Deep-drawn base & lid

Jacket & base butt-welded

Seams rolled flat & finely sanded

Functions & advantages

The BOLZ INTEC product portfolio consists of drums, hoppers, pressure vessels and special constructions made of thin-walled stainless steel (1.0 - 3.0 mm). For many years, we have established ourselves as a reliable partner for companies that place the highest demands on their production equipment. Our experience and engineering skills are particularly evident in our 150 liter stainless steel drum. This barrel is the result of years of research and development and close cooperation with our clients.

Contamination-free production

Die speziell veredelte Edelstahloberfläche sorgt für höchste Reinheit und minimiert die Partikelanhaftung. Unser Edelstahlfass 150 Liter ist darauf ausgelegt, Kontaminationen in Ihrer Produktion effektiv zu verhindern. Dank seiner veredelten Edelstahloberfläche wird die Anhaftung von Partikeln auf ein Minimum reduziert. Dies ist besonders wichtig in Branchen, in denen selbst kleinste Verunreinigungen erhebliche Konsequenzen nach sich ziehen können.

Reproducible product quality

Die makellose Oberfläche unseres Edestahlfass 150 Liter reduziert das Risiko von Produktionsunterbrechungen und Produktrückrufen. In der Fertigung ist die gleichbleibende Qualität von entscheidender Bedeutung. Mit dem Edelstahlfass 150 Liter profitieren Sie von einer höheren Zuverlässigkeit und können Ihre Prozesse effizienter gestalten, während gleichzeitig die höchsten Qualitätsstandards eingehalten werden.

Compliance with the highest standards

Das Edelstahlfass 150 Liter entspricht selbst strengsten Richtlinien und ist ideal für Bereiche, die hohe Hygienestandards erfordern, besonders in der Pharma- und Kosmetikindustrie. Unser Edelstahlfass 150 Liter erfüllt die Vorgaben von GMP (Good Manufacturing Practice) und EHEDG (European Hygienic Engineering and Design Group) vollständig. Alle unsere Fässer werden nach den aktuellen GMP-Richtlinien und der DIN EN ISO 9001:2008 Norm hergestellt, für höchste Sicherheit und Qualität.

Hygienic properties

Einfache Reinigung: Dank der glatten Oberflächenstruktur lässt sich unser Edelstahlfass 150 Liter mühelos reinigen, was die Einhaltung der Hygieneanforderungen in sensiblen Bereichen unterstützt. Korrosionsbeständigkeit: Der verwendete Edelstahl ist besonders korrosionsbeständig, was die Langlebigkeit des Fasses erheblich erhöht.

Durability & safety

Robust construction: The sturdy material reliably protects your products and offers long-lasting safety. Airtight seal: The lid with FDA-certified seals ensures an airtight seal that reliably protects the contents from external influences. Sustainability: Our 100-liter stainless steel drum is rust-free, resistant to light and UV rays, odorless and tasteless and fully recyclable.

Technical details & variants

| Lidded drums | |

|---|---|

| Volume | 0.5 to 400 liters |

| Materials |

1.4301 (AISI 304) 1.4404 (AISI 316L) 1.4435 (AISI 316L) 2.4602 (Hastelloy C22) Special materials |

| Surfaces |

Mill finish / 2B (IIIC) Brushed Ground to Ra ' 0.25 µm Electropolished up to Ra ' 0.25 µm OGF process up to Ra ' 0.05 µm |

| Material thicknesses | 1.0 to 2.0 mm |

| Seals |

Silicone (platinum-cured) EPDM Viton FEP coated silicone |

| Standard |

With flat base Incl. lid, silicone seal and clamping ring 1.4301 Optionally with or without beads Weld seams rolled flat and finely ground Rim not welded |

| GMP versions |

Welded edging Surface ground Ra ' 0.8 µm inside; Ra ' 1.5 µm outside Optionally electropolished |

| Special version |

Welded edging Foot hoop dished bottom Inclined bottom Conical design Attachments: nozzles, sockets etc. Hazardous goods approval according to BAM Other variants and dimensions on request |

Lidded drum SKE-1-632

Lidded drum SKE-1-633

Lidded drum SKE-1-671

| Bung barrels | |

|---|---|

| Volume | 0.5 to 200 liters |

| Materials |

1.4301 (AISI 304) 1.4404 (AISI 316L) 1.4435 (AISI 316L) 2.4602 (Hastelloy C22) Special materials |

| Surfaces |

Mill finish / 2B (IIIC) Brushed Ground to Ra ' 0.25 µm Electropolished up to Ra ' 0.25 µm OGF process up to Ra ' 0.05 µm |

| Material thicknesses | 1.25 to 1.5 mm |

| Seals |

PTFE Silicone (platinum cross-linked) |

| Standard |

With dished bottom and foot ring 2" or 3/4" spigot Optionally with or without beads Not stackable Edging not welded |

| Special version | Welded edging |

| Batch container | |

|---|---|

| Volume | 70 to 500 liters |

| Materials |

1.4301 (AISI 304) 1.4404 (AISI 316L) 1.4435 (AISI 316L) 2.4602 (Hastelloy C22) Special materials |

| Surfaces |

Mill finish / 2B (IIIC) Brushed Ground to Ra ' 0.25 µm Electropolished up to Ra ' 0.25 µm OGF process up to Ra ' 0.05 µm |

| Material thicknesses | 1.25 to 1.5 mm |

| Seals |

Silicone (platinum-cured) EPDM Viton FEP coated silicone |

| Standard |

With clapper base and foot ring Curved lid optionally with clamps Optionally with and without beading Not forkable Edging not welded |

| Special version |

Curved lid can be swiveled Welded edging |

| Conical barrels | |

|---|---|

| Volume | 50 to 180 liters |

| Materials |

1.4301 (AISI 304) 1.4404 (AISI 316L) 1.4435 (AISI 316L) 2.4602 (Hastelloy C22) Special materials |

| Surfaces |

Mill finish / 2B Ground to Ra ' 0.25 µm Electropolished up to Ra ' 0.25 µm OGF process up to Ra ' 0.05 µm |

| Seals | Silicone |

| Standard |

With flat base Incl. lid, silicone seal and clamping ring 1.4301 Optionally with or without beading Can be forked |

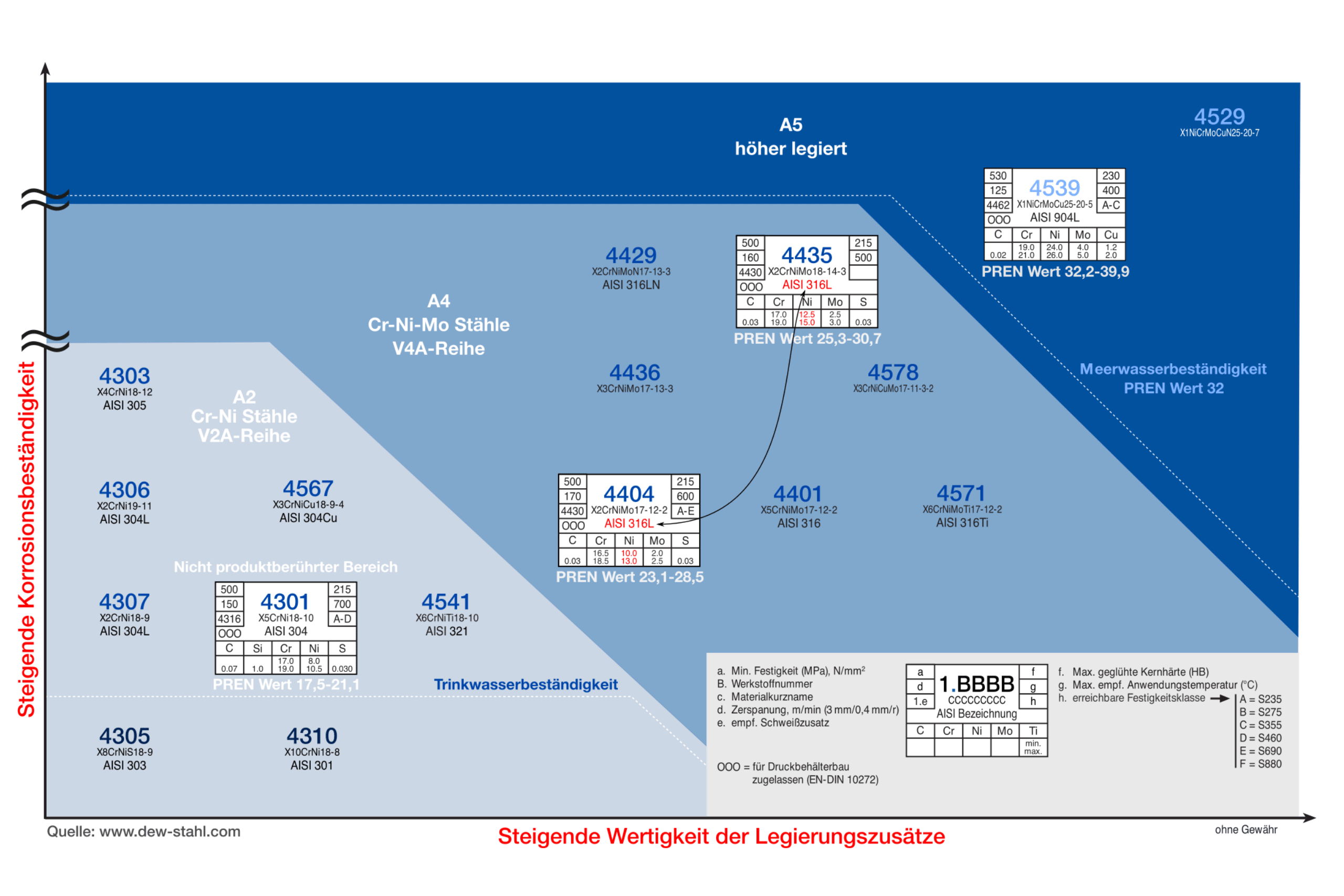

Materials for all requirements

1.4301 (AISI 304)

Corrosion-resistant austenitic steel, versatile, good weldability, suitable for chemical and food applications.

1.4404 (AISI 316L)

Austenitic steel with added molybdenum for high corrosion resistance and good weldability, versatile in use.

1.4435 (AISI 316L)

Austenitic steel with increased molybdenum content and low ferrite content (' 3 %) for improved corrosion resistance and higher resistance to pitting.

1.4539 (AISI 904L)

Heat-resistant, high-alloy steel with increased chromium and nickel content, excellent resistance to acids and corrosion at high temperatures.

2.4602 Hastelloy C22

High-alloy nickel-chromium-molybdenum steel, excellent corrosion resistance to aggressive media such as acids, chlorine and oxidizing substances.

Special materials

In addition to the materials mentioned, BOLZ INTEC also processes other materials, depending on the customer's specifications and requirements.

Surfaces for all processes

Mill finish / 2B

Standard surface after rolling, uniform smoothness and roughness for a wide range of applications.

Brushed

Matt finish thanks to brushing, increased scratch resistance, ideal for aesthetic and functional applications.

Ground up to

Ra ' 0.4 µm

Fine, even surface, especially for applications with high purity requirements and aesthetic demands.

Electropolished up to

Ra ' 0.25 µm

High-gloss finish thanks to electrochemical polishing, maximum corrosion resistance and surface cleanliness.

OGF process up to

Ra ' 0.05 µm

Optimized Grind Finishing® is a process developed by BOLZ INTEC and the University of Constance for minimal particle adhesion.

Optionen zur Anpassung für das Edelstahlfass 150 Liter

Flare ring & reducer

Handle variants & edging

Dosing unit & inlet pieces

Accessories for the 150 l stainless steel drum

Barrel rollers & barrel trolleys

Drum emptying system

Transport & emptying system (EPS)

The Optimized Grind Finishing® process (OGF)

In the pharmaceutical, chemical and food industries, reducing build-up in containers plays a crucial role in efficiency and product quality. Substances that stick to the inner walls can lead to increased cleaning effort, product losses and potential contamination, which not only causes costs but also ties up valuable resources. Especially in industries where EHEDG (European Hygienic Engineering & Design Group) and Hygienic Design certifications are becoming increasingly important, minimizing adhesion is an indispensable factor.

Research conducted by BOLZ INTEC in collaboration with the University of Constance has shown that the method used to process stainless steel surfaces is crucial for reducing adhesion. Different grinding techniques lead to different adhesion behavior, despite the same Ra values. The OGF process from BOLZ INTEC achieves particularly low particle adhesion.

Easy cleaning & minimal adhesion

The Optimized Grind Finishing® (OGF) process leads to a low adhesion of particles on the surfaces of the containers. This significantly improves cleaning efficiency and reduces the risk of contamination of product batches.

Reproducible surface quality

The OGF process enables reproducible surface quality. In contrast to conventional processes, in which variable factors such as manual contact pressure or the quality of abrasives play a role, the OGF process offers consistent surface quality.

Visual aesthetics and low number of errors

The stainless steel surfaces treated with the OGF process have an attractive appearance and defects in the surface structure are significantly reduced thanks to the fine and gentle removal process. This is particularly important in industries that place high demands on safety.

Improved corrosion protection

The electropolishing process not only improves the optical quality, but also results in chemical changes that lead to improved corrosion protection. This is particularly relevant for applications in chemical and pharmaceutical processes.

Reduced risk of batch contamination

The improvement in cleaning behavior through the OGF process leads to a significant reduction in residual dirt adhesion in the containers. This significantly reduces the risk of contamination between different product batches.

Applicability in critical industries

The process is seen as particularly advantageous for critical industries such as nanotechnology or biotechnology and pharmaceutical technology, where the highest purity requirements and the avoidance of contamination are of crucial importance.

Increased efficiency through minimal adhesion

Simply send an e-mail and receive the download link

Services from BOLZ INTEC

Technical advice & design

Barrel repair

Simoflex® drum wash

Electropolishing

Why you should choose BOLZ INTEC as the manufacturer for your stainless steel drums

Tradition & innovation since 1919

BOLZ INTEC specializes in the manufacture of stainless steel drums, pressure vessels, agitator vessels, transport containers and transfer systems for hygiene-sensitive industries.

High vertical integration

BOLZ INTEC has acquired outstanding expertise in the machining of stainless steels and special materials such as Hastelloy. Combined with the skills and abilities of our team, this enables us to achieve maximum vertical integration. All production steps are carried out in-house. BOLZ INTEC is therefore able to react extremely flexibly to customer delivery date requests and guarantee unique quality.

Customized solutions

Our design department designs, plans and develops practical products according to our customers' requirements. These include, for example, containers for pasty substances or liquids, transport containers for UN hazardous goods, cans for the storage and transfer of active ingredients, suction hoods for dust-free container loading and much more.

One-off production & small series

BOLZ INTEC also manufactures custom-made products and small series.

Machines for perfect surfaces

Nothing in the BOLZ INTEC machine park is off the shelf. From the deep-drawing press to the electropolishing system, we work with special machines that have been developed according to our own specifications in order to meet the highest standards of quality and precision.

Traceability & reproducibility

BOLZ INTEC's QM system and our intensive testing procedures ensure the consistent quality of the stainless steel surfaces manufactured by BOLZ INTEC. In this way, we make a decisive contribution to the traceability of products in critical industries.

Trust & security

Our striving for perfect quality, state-of-the-art production methods, but also craftsmanship and know-how are the basis for the superior BOLZ INTEC quality, which means safety and reliability for our customers. It is therefore not surprising that 80% of our customers have reordered every year for the last 10 years.

Comprehensive certification

We regularly have our quality certified externally: DIN 9001:2015, DIN EN ISO 3834-2:2006-03, DIN EN ISO 115085-2/CL1. We are a specialist company according to WHG §19/1 and carry out process tests according to DIN EN ISO 15614-1, operator tests according to DIN EN 1418. BOLZ INTEC fulfills the Pressure Equipment Directive-2014-68-EU/AD-2000 HPO and employs Intern. Welding engineers (DVS/IIW 1170).

What sets us apart from the competition

Flexibility & adaptability

Das Edelstahlfass 150 Liter von BOLZ INTEC ist nicht nur für seine Qualität und Langlebigkeit bekannt, sondern auch für seine Vielseitigkeit und die Möglichkeit individueller Anpassungen. Wir bieten Ihnen eine breite Palette an Edelstahlfässern und auch maßgeschneiderte Lösungen, die exakt auf Ihre Bedürfnisse zugeschnitten werden können. Ob Sie ein Deckelfass, ein konisches Fass oder ein Spundfass benötigen – wir haben das passende Edelstahlfass 150 Liter für Sie. Alle unsere Fässer, Behälter und Apparaturen sind so konzipiert, dass sie den spezifischen Anforderungen der unterschiedlichsten Branchen gerecht werden.

The right stainless steel drum for every substance

Ob Pulver oder Granulat, ob pastöse oder flüssige Medien – mit einem Edelstahlfass 150 Liter von BOLZ INTEC können Sie jede Substanz absolut sicher lagern und transportieren. Unsere Edelstahlfässer sind speziell darauf ausgelegt, die besonderen Anforderungen der Pharmaindustrie, Biotechnologie, Feinchemie oder Kosmetikindustrie zu erfüllen. Sie sind robust, sicher und einfach zu handhaben. Zudem sind sie für den Einsatz in hygienesensiblen Bereichen bestens geeignet, was sie zur idealen Wahl für die Lagerung und den Transport Ihrer wertvollen Produkte macht.

Perfect quality through precise manufacturing

BOLZ INTEC steht für Perfektion in der Produktion. Das Edelstahlfass 150 Liter wird sowohl in Einzel-, als auch in Serienfertigung hergestellt. Unsere hohe Fertigungstiefe gewährleistet dabei eine flexible Reaktion auf Lieferwünsche und ermöglicht schnelle Lieferzeiten. Die verwendeten Werkstoffe aus Chrom-Nickel-Stahl sind rostfrei, lichtbeständig, geruchs- und geschmacksneutral sowie diffusionsecht. Durch eine präzise und flexible Produktionsweise erfüllen wir nahezu jeden Kundenwunsch. So können Sie sicher sein, dass Ihr Edelstahlfass 150 Liter exakt auf Ihre Bedürfnisse abgestimmt ist und alle Anforderungen Ihrer Branche erfüllt.

Sustainability & longevity

Our stainless steel drums are characterized by their extreme durability. Not only are they rustproof and resistant to light and UV radiation, they are also inert and odorless and tasteless. They are also 100% recyclable, making them an environmentally friendly choice. In addition to environmentally friendly production methods, BOLZ INTEC also offers a repair service for drums - another plus point for sustainability and also for your ROI.

Unlimited possibilities for customization

Jedes Unternehmen hat seine eigenen Anforderungen und jedes Produkt stellt andere Herausforderungen an die Lagerung und den Transport. Deshalb bieten wir bei BOLZ INTEC zahlreiche Optionen zur individuellen Anpassung für Ihr Edelstahlfass 150 Liter an. So können Sie sicher sein, dass Ihr Edelstahlfass 150 Liter perfekt auf Ihre Bedürfnisse zugeschnitten ist.

Extensive accessories for your stainless steel barrel

Für jedes Edelstahlfass 150 Liter bieten wir das passende Zubehör an, um Ihre Arbeitsprozesse noch effizienter zu gestalten. Dazu gehören unter anderem Fassroller, Fasswagen, Fass-Entleerungssysteme, Transport- und Entleersysteme (EPS) sowie die Simoflex® Fasswäsche. Darüber hinaus stellen wir Ihnen gerne Musterfässer und Fassroller für kostenlose Tests zur Verfügung, damit Sie sich von der Qualität unserer Produkte überzeugen können.

The last barrel arrived last week. We received all the parts we ordered on time. Your prompt and professional support enabled us to keep to our schedule. Finally, I would like to thank you for your constructive, professional and reliable cooperation."

the customer has accepted the funnel and is very satisfied.

I wanted to thank you again for the fast processing and delivery..."

Thank you very much for this good news and please pass on our thanks to your production staff and all those involved, as it has now been possible to produce the tanks for us at very short notice. You have helped us a great deal."

The containers were inspected. The result is very positive, no defects were found. The qualification was also completed."

How the collaboration begins

Request

Send us an e-mail, give us a call or book an appointment via Calendly. In a phone call with one of our competent contacts, we will clarify a few questions in advance using checklists and send you a non-disclosure agreement (NDA).

Test phase

Based on your objectives and specifications, you will receive drums, containers, funnels and accessories from our test center - as required - to try out and test. You can use your test equipment to verify or adapt the specifications of your request.

Offer

During a visit to your premises, our competent contact partners will advise you on clarifying any final questions, finding solutions to identified problems and defining your exact requirements. We can then start production.

Our project team looks forward to your inquiry

Sie haben Fragen zum Edelstahlfass 150 Liter oder unseren Leistungen und möchten von einem unserer kompetenten Mitarbeiter beraten werden?

Give us a call or send us an e-mail. We will make time for you and will be happy to call you back if you wish.

Order & request

Our stainless steel barrel in other sizes

You ask, we answer

Das Edelstahlfass 150 Liter kann mit einer hohen Korrosionsbeständigkeit, Langlebigkeit und ausgezeichneten hygienischen Eigenschaften glänzen. Diese Vorteile machen es ideal den Einsatz in hygienesensiblen Produktionsprozessen.

Yes, BOLZ INTEC offers a range of options with which the drum can be adapted to the customer's specific needs and also offers special designs.

10 years, with regular maintenance even up to 20 years!

Smoothing the stainless steel surface plays a key role in ensuring sterility, especially in areas with high hygiene standards, for several reasons:

Reduced surface roughness: A smoothed stainless steel surface minimizes the number of cracks and crevices in which microorganisms could colonize. This makes cleaning and disinfection easier, as germs have fewer places to hide.

Easy to clean: A smooth surface enables particularly thorough and effective cleaning of stainless steel, which is essential to ensure a low bacterial load.

Improved corrosion resistance: Smoothing processes such as electropolishing increase the chrome content on the surface, which improves corrosion resistance. This protects the surface from frequently used cleaning agents and disinfectants, especially in hygiene-sensitive industries.

Antibacterial effect: The chrome-nickel surface of stainless steel has additional antibacterial properties that help to maintain sterility.

The corrosion resistance of stainless steel is crucial for maintaining sterility, especially in areas with high hygiene requirements, through the following mechanisms:

Protective layer of oxides: Stainless steel forms an ultra-thin but dense chromium oxide layer that protects the metal from external influences. This protective layer prevents the penetration of microorganisms and chemicals, which helps to ensure sterility.

Self-healing properties: If the protective layer is damaged, it regenerates itself as long as the environmental conditions are not extreme. As a result, the surface of the stainless steel remains corrosion-resistant, which is very important for maintaining sterility.

Resistance to aggressive cleaning agents: Stainless steel can withstand high temperatures and aggressive cleaning agents used for sterilization in hygiene-critical areas. This resistance prevents damage to the surface and thus reduces the risk of germs being introduced.

Inert to environmental influences: Stainless steel does not react with the stored products or cleaning agents, which ensures the purity and sterility of the products.

Stainless steel drums used in industries with the highest hygiene requirements must meet specific standards to ensure the safety and quality of the products manufactured. The most important requirements include

GMP standard: Stainless steel drums must comply with Good Manufacturing Practice (GMP) standards, which place high demands on hygiene and quality assurance.

Oberflächengüte: Die Fässer sollten über eine glatte und spaltfreie Oberfläche verfügen, die elektropoliert und bis zu einer Rauheit von RA< 0,25µm geschliffen ist. Dies erleichtert die Reinigung und verhindert die Anhaftung von Partikeln.

Materialqualität: Die Fässer werden aus hochwertigen Edelstahltypen wie 1.4301/AISI 304, 1.4404/AISI316L oder Hastelloy 2.4602/C22 gefertigt, die korrosionsbeständig sind und für den Einsatz mit aggressiven Chemikalien geeignet sind.

Hygienic design: Hygienic design is crucial to avoid contamination. This includes special welding techniques such as TIG welding and the use of clamping ring covers with suitable seals.

Documentation and traceability: Full documentation is provided to ensure the traceability of the material, which is essential for quality assurance.

Stainless steel offers numerous advantages for the storage of pharmaceutical and cosmetic products:

Corrosion resistance: Stainless steel is characterized by its high resistance to corrosion, which makes it particularly suitable for storing products that come into contact with aggressive chemicals or cleaning agents.

Hygiene and sterility: Thanks to its smooth surface, the growth of microorganisms on stainless steel is prevented. This makes cleaning easier and helps to maintain sterility, which is very important in the pharmaceutical industry.

Durability and temperature resistance: Stainless steel is robust and can withstand extreme temperatures, which is particularly important for storing temperature-sensitive products.

Protection of product quality: Stainless steel containers offer protection against external influences such as air pollution, oxidation and particles from packaging, which preserves the quality of the products in the long term.

Food-safe properties: Stainless steel is tasteless and resistant to fruit acids, which also makes it ideal for cosmetic products that are sensitive to changes.

The Optimized Grind Finishing® (OGF) process offers numerous advantages for stainless steel drums:

Minimized particle adhesion: OGF achieves a surface finish that significantly reduces the adhesion of particles. This is particularly relevant in areas where the highest hygiene standards are required, such as in the pharmaceutical and food industries.

Easier cleaning: Thanks to the optimized surface, the drums can be cleaned more easily and thoroughly. This reduces the cleaning effort and the associated costs and increases efficiency in production processes that have strict cleanliness requirements.

Advanced surface treatment: OGF represents a significant advance in the surface treatment of stainless steel, as it ensures a uniform and high-quality finish.

These advantages make the OGF process particularly attractive for industries that rely on the highest hygiene and quality standards.

Stainless steel drums that comply with GMP (Good Manufacturing Practice) standards must meet defined requirements in order to guarantee the high hygiene standards and quality requirements of the pharmaceutical industry. These include:

Material quality: The drums are made of high-quality stainless steel (e.g. 1.4404/AISI 316L), which is corrosion-resistant, rustproof and hygienic. The material is odorless, tasteless and diffusion-resistant, making it ideal for storing sensitive substances.

Surface finish: The stainless steel surface is optimized to ensure minimal particle adhesion. This reduces the risk of contamination and makes cleaning easier, which is particularly important for compliance with hygiene standards.

Design features: The drums are butt-welded and gap-free, which makes cleaning easy and residue-free. This is crucial to ensure the purity of the stored products.

Closure systems: Stainless steel drums have airtight closure systems with reusable lids, seals and clamping rings that protect the contents from external influences and preserve the quality of the products.

Certifications: The drums are manufactured in accordance with the current GMP standards and DIN EN ISO 9001:2008. This ensures that they meet the highest quality and safety requirements and are suitable for use in hygiene-sensitive industries.

Adaptability: Stainless steel drums are available in different sizes and capacities and can be adapted to specific process requirements. This offers flexibility for different applications in the pharmaceutical industry.

Stainless steel drums for pasty and liquid media differ in several aspects that are tailored to the specific requirements of the respective media:

Emptying systems:

Special emptying systems are required for pasty media, which enable almost residue-free emptying. These systems often use compressed air or mechanical ejection plungers to gently push the medium out of the drum.

Liquid media can usually be emptied more easily by gravity or pumps, whereby standard systems are sufficient for emptying.

Seals and closures:

Pasty media often require special seals and closures to ensure that the medium does not escape and that no air bubbles form that could hinder emptying. With liquid media, the requirements for tightness are also high, but the systems are often less complex as liquids flow more easily.

Material and construction:

The stainless steel drum is made of high-quality stainless steel, which is corrosion-resistant. However, drums for pasty media can have additional reinforcements or special internal coatings to prevent the medium from sticking.

The design can also have differences in surface treatment to optimize cleaning and handling of the respective media.

Areas of application:

Pasty media are often stored in the food, cosmetics and pharmaceutical industries, where gentle handling and precise dosing are important. Liquid media are also used in these industries, as well as in the chemical industry, where the storage and transportation of liquids such as chemicals or oils is paramount.

Das Edelstahlfass 150 Liter von BOLZ INTEC zeichnet sich durch eine überlegene Reinigungseffizienz aus. Dank des patentierten Optimized Grind Finishing® (OGF) Verfahrens weist die Oberfläche unseres Edelstahlfasses 150 Liter eine extrem geringe Rauheit auf. Dies führt zu einer deutlich reduzierten Partikelanhaftung im Vergleich zu herkömmlichen Edelstahlfässern. In der Praxis bedeutet dies, dass unser Edelstahlfass 150 Liter bis zu 60% schneller und mit bis zu 40% weniger Reinigungsmitteln gereinigt werden kann. Diese Effizienzsteigerung macht unser Edelstahlfass 150 Liter besonders wirtschaftlich im Langzeitbetrieb.

BOLZ INTEC bietet eine Vielzahl von Anpassungsmöglichkeiten für das Edelstahlfass 150 Liter, um individuellen Prozessanforderungen gerecht zu werden. Unser Edelstahlfass 150 Liter kann mit verschiedenen Rührwerkstypen ausgestattet werden, von einfachen Propellerrührern bis hin zu komplexen Magnetrührwerken für sterile Anwendungen. Für das Edelstahlfass 150 Liter sind zudem unterschiedliche Heiz- und Kühlsysteme verfügbar, einschließlich Doppelmäntel und elektrischer Heizungen. Wir können das Edelstahlfass 150 Liter auch mit speziellen Einlässen, Auslässen und Probeentnahmesystemen ausstatten. Darüber hinaus bieten wir maßgeschneiderte Automatisierungs- und Steuerungslösungen, die es ermöglichen, das Edelstahlfass 150 Liter nahtlos in bestehende Produktionslinien zu integrieren.

Der Einsatz unseres Edelstahlfass 150 Liter kann die Produktqualität in der pharmazeutischen Industrie signifikant verbessern. Die hochreine Oberfläche des Edelstahlfasses 150 Liter minimiert das Risiko von Kontaminationen und chemischen Reaktionen. Unser Edelstahlfass 150 Liter ist aus ferritarmem Edelstahl gefertigt, was die Bildung von Metallionen verhindert, die empfindliche pharmazeutische Produkte beeinträchtigen könnten. Zudem ermöglicht die präzise Temperaturkontrolle unseres Edelstahlfasses 150 Liter eine exakte Steuerung von Reaktionsbedingungen, was zu einer konsistenteren Produktqualität führt. Diese Eigenschaften machen unser Edelstahlfass 150 Liter zu einer idealen Wahl für GMP-konforme Produktionsprozesse in der Pharmaindustrie.

Unser Edelstahlfass 150 Liter ist mit mehreren fortschrittlichen Sicherheitsfeatures ausgestattet. Jedes Edelstahlfass 150 Liter verfügt über ein Überdruckventil, das präzise auf den maximalen Betriebsdruck eingestellt ist. Zusätzlich integrieren wir auf Wunsch Berstscheiben als redundantes Sicherheitssystem. Eine Besonderheit unseres Edelstahlfasses 150 Liter ist das optionale digitale Überwachungssystem, das Druck und Temperatur in Echtzeit überwacht und bei Abweichungen sofort alarmiert. Diese Kombination aus mechanischen und digitalen Sicherheitssystemen macht unser Edelstahlfass 150 Liter zu einer der sichersten Optionen auf dem Markt.

BOLZ INTEC bietet umfassende Unterstützung bei der Validierung und Qualifizierung des Edelstahlfasses 150 Liter für regulierte Industrien wie Pharma und Biotechnologie. Für jedes Edelstahlfass 150 Liter stellen wir eine vollständige Dokumentation bereit, die Materialzertifikate, Schweißprotokolle und detaillierte Fertigungsunterlagen umfasst. Unser Expertenteam unterstützt Sie bei der Durchführung von IQ (Installationsqualifizierung), OQ (Funktionsqualifizierung) und PQ (Leistungsqualifizierung) für das Edelstahlfass 150 Liter. Wir bieten auch maßgeschneiderte Testprotokolle an, um die Konformität des Edelstahlfasses 150 Liter mit spezifischen regulatorischen Anforderungen nachzuweisen. Zusätzlich können wir FAT (Factory Acceptance Tests) und SAT (Site Acceptance Tests) für das Edelstahlfass 150 Liter durchführen, um einen reibungslosen Validierungsprozess zu gewährleisten.

Sie haben Fragen oder suchen Beratung betreffend das Edelstahlfass 150 Liter?

Please do not hesitate to contact us by phone or e-mail.